Real Case A

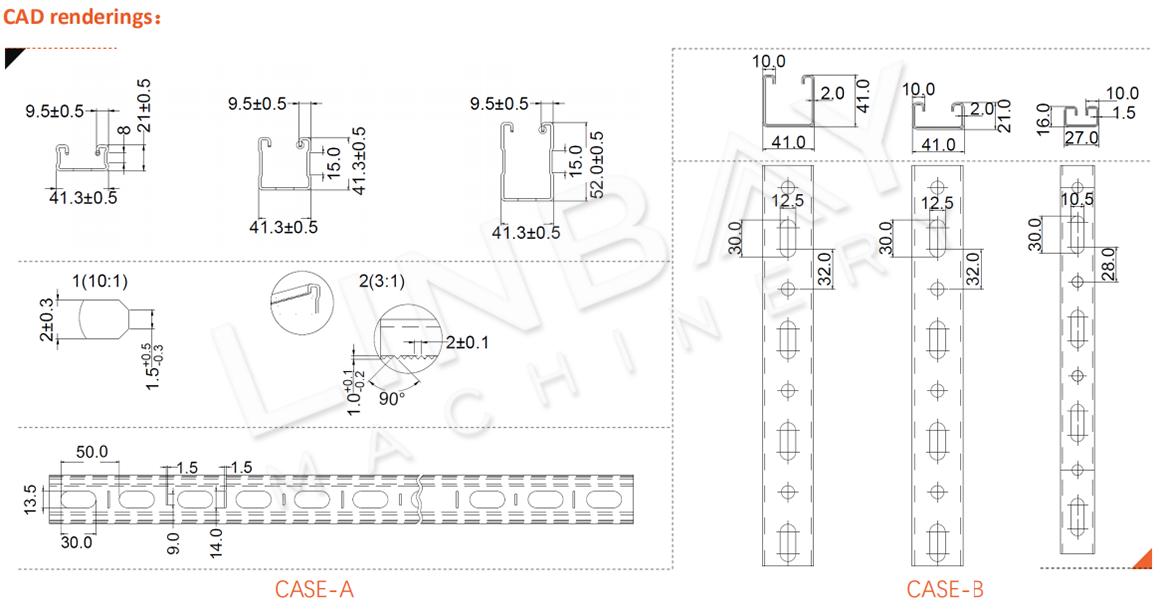

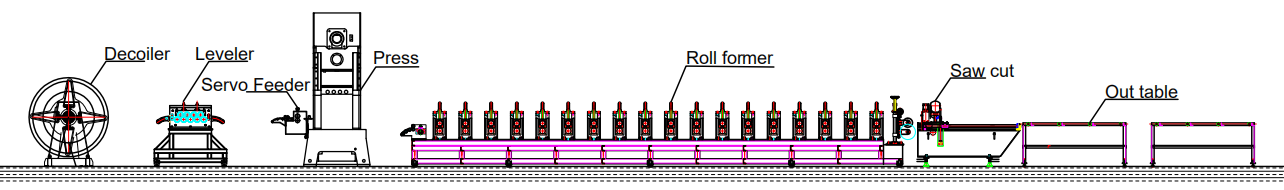

Real Case A  Description: This strut channel production line is suitable for making many sizes of strut channels. In this case, we produce 5 different sizes totally. Therefore, we recommend burr-free saw cutting to reduce blade’s cost and changing blades time. If you want a non-stop cut, we could also turn this shear into flying one to increase working speed. Real case B

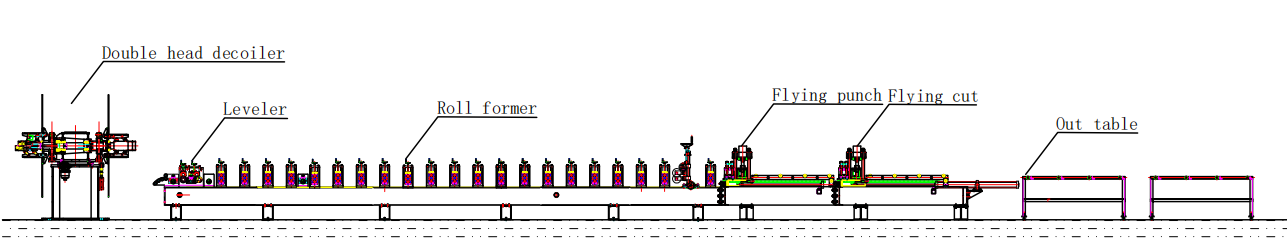

Description: This strut channel production line is suitable for making many sizes of strut channels. In this case, we produce 5 different sizes totally. Therefore, we recommend burr-free saw cutting to reduce blade’s cost and changing blades time. If you want a non-stop cut, we could also turn this shear into flying one to increase working speed. Real case B  Description: This strut channel production line is made for our Pakistani customer finished in 2018. This is a similar line of SAMCO, Canada using flying hydraulic punch and flying hydraulic cut, it means non-stop punch and non-stop cut. Normal working speed reach 20m/min. Also we suggest you a rotary punch, whose speed can realize 40m/min if you want a higher-yield production line.

Description: This strut channel production line is made for our Pakistani customer finished in 2018. This is a similar line of SAMCO, Canada using flying hydraulic punch and flying hydraulic cut, it means non-stop punch and non-stop cut. Normal working speed reach 20m/min. Also we suggest you a rotary punch, whose speed can realize 40m/min if you want a higher-yield production line.

| Strut Channel Roll Forming Machine | ||

| Machinable Material : | A) Hot-rolled and cold rolled steel | Thickness(MM): 1.8-2.6 , 2-2.5 |

| B) Hot-dip galvanized sheet | ||

| C) Pre-Galvanized Steel | ||

| D) Mill(Plain/Black) Steel | ||

| E) Aluminum | ||

| F) Stainless Steel | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | G250 Mpa-G550 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press (Optional) |

| Forming station : | 20-22 | * According to your profile drawings |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Gearbox drive | * Chain drive (Optional) |

| Machine structure: | Forged Iron station | * Wall panel (Optional) |

| Forming speed : | 15-20 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

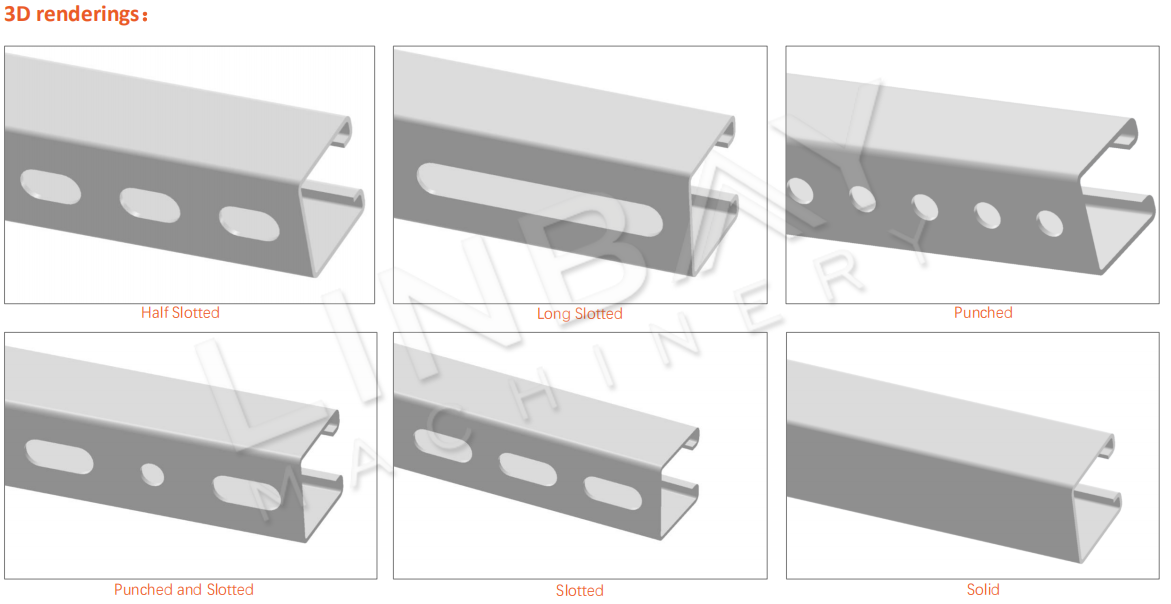

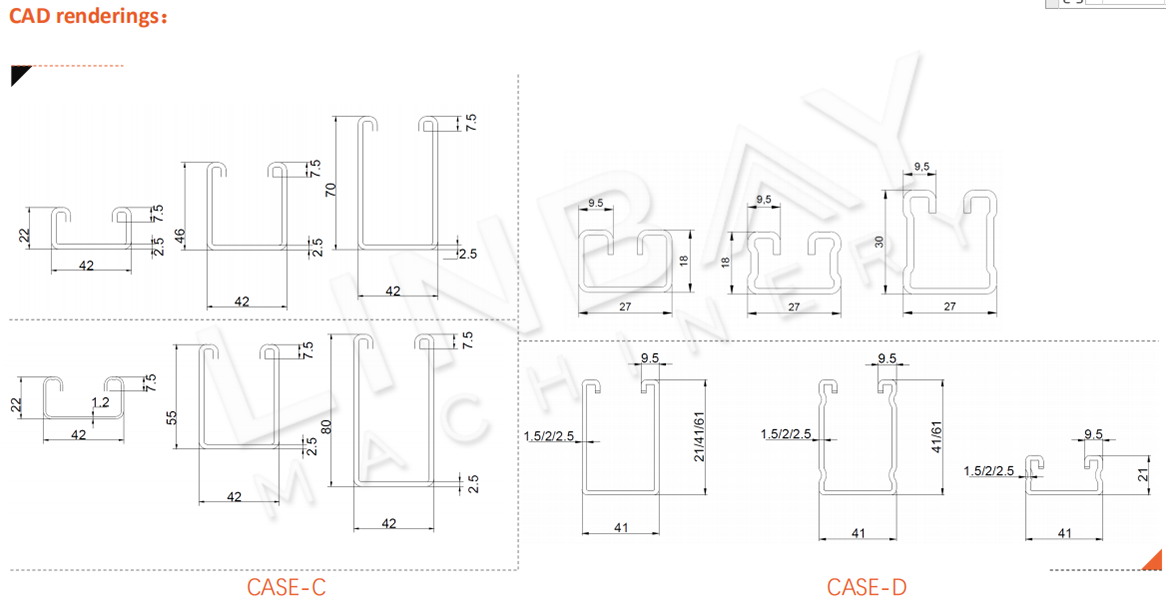

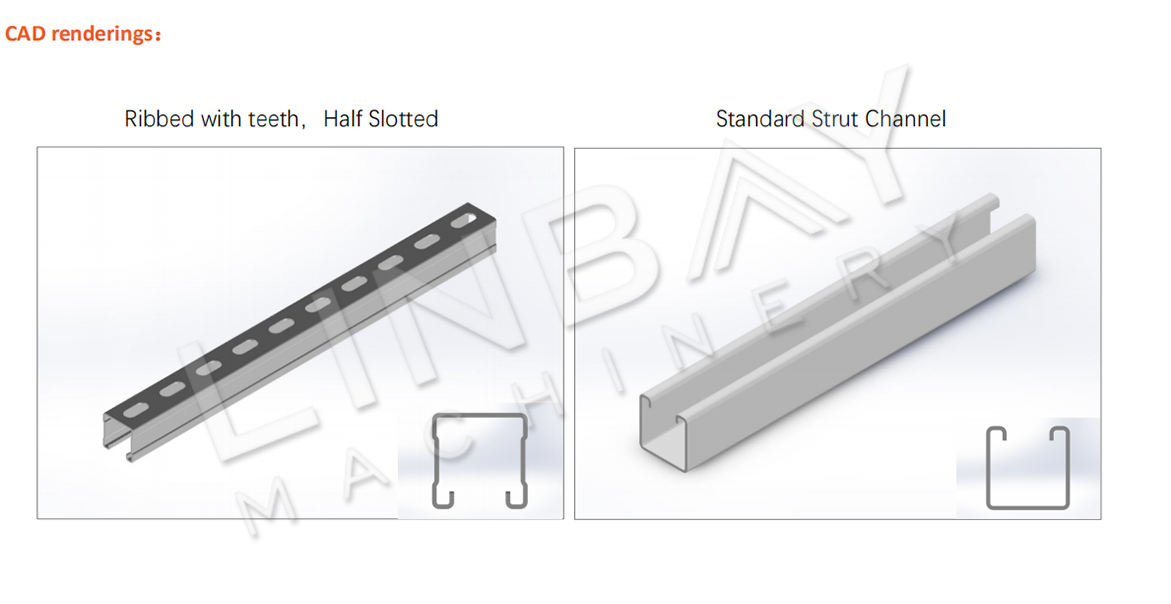

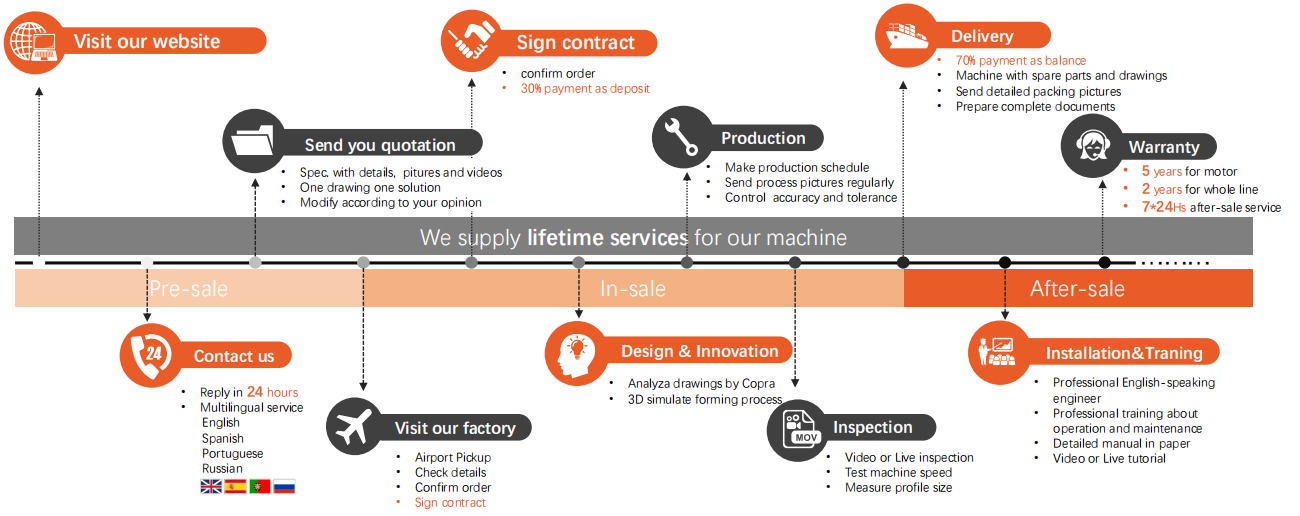

1. Q: What kinds of experience do you have in producing strut channel roll forming machine? A: We have experience of exporting our strut channel roll formers to Pakistan, Mexico, Peru and Malaysia etc. We have produced solid channels, slotted channels, punched channels, standard channels etc. We are confident to solve your strut channel problem. 2. Q: How many sizes can be made in one machine? A: One machine could produce one same width with different heights like 41x21, 41x41, 41x62, 41x82 or 27x18, 27x30. 3. Q: What is delivery time of strut channel machine? A: 80 days to 100 days depends on your drawing. 4. Q: What is your machine speed? A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. if you want a higher speed like 40m/min, we give you a solution with rotary punch system, which punch speed is up to 50m/min. 5. Q: How could you control your machine’s precision and quality? A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners. 6. Q: What is your after-sales service system? A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1. Q: What kinds of experience do you have in producing strut channel roll forming machine? A: We have experience of exporting our strut channel roll formers to Pakistan, Mexico, Peru and Malaysia etc. We have produced solid channels, slotted channels, punched channels, standard channels etc. We are confident to solve your strut channel problem. 2. Q: How many sizes can be made in one machine? A: One machine could produce one same width with different heights like 41x21, 41x41, 41x62, 41x82 or 27x18, 27x30. 3. Q: What is delivery time of strut channel machine? A: 80 days to 100 days depends on your drawing. 4. Q: What is your machine speed? A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. if you want a higher speed like 40m/min, we give you a solution with rotary punch system, which punch speed is up to 50m/min. 5. Q: How could you control your machine’s precision and quality? A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners. 6. Q: What is your after-sales service system? A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.