Description

This Ridge Cap roll forming machine is used in roofing sheet. The normal raw material is 0.3-0.8mm thickness. Normal working speed is 10-25m/min. It has many different shapes, we can make all kinds of machine if you can offer the profile to us. We are very profesional in OEM roll forming machine.

Technical Specifications

| Ridge cap roll forming machine | |||

| No. | Item | Specification | Optional |

| 1 | Suitable material | Type:Galvanized Coil, PPGI, Carbon steel Coil | |

| Thickness(mm):0.3-0.8 | |||

| Yield strength: 250 - 550MPa | |||

| Tensil stress( Mpa):G350Mpa-G550Mpa | |||

| 2 | Nominal forming speed(m/min) | 10-25 | Or according to your requirement |

| 3 | Forming station | 14 | According to your profile |

| 4 | Decoiler | Manual decoiler | Hydraulic decoiler or double head decoiler |

| 5 | Main machine motor | Sino-German Brand | Siemens |

| 6 | PLC brand | Panasonic | Siemens |

| 7 | Inverter brand | Yaskawa | |

| 8 | Driving system | Chain drive | Gearbox drive |

| 9 | Rollers’ materail | Steel #45 | GCr15 |

| 10 | Station structure | Wall panel station | Forged Iron stationOr torri stand structure |

| 11 | Punching system | No | Hydraulic punching station or Punching press |

| 12 | Cutting system | Post-cutting | Pre-cutting |

| 13 | Power supply requirement | 380V 60Hz | Or according to your requirement |

| 14 | Machine color | Industrial blue | Or according to your requirement |

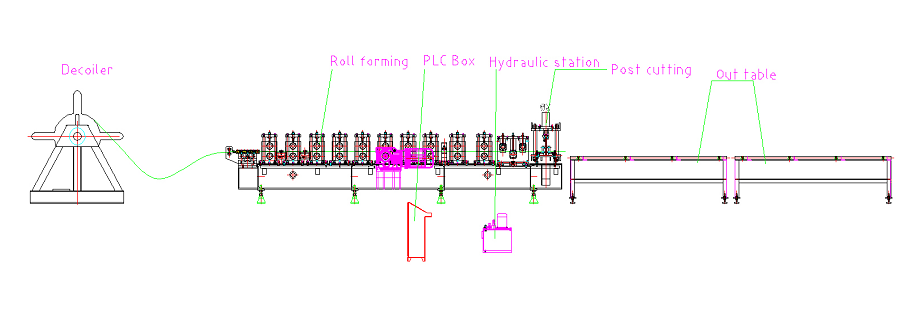

Flow Chart