Real Case A

Real Case A  Description: This roof tile roll forming machine we exported to Mexico, it use the new type of cut and press system, the new mold can make more beautiful pitch and it controls length precision within +/- 0.5mm.

Description: This roof tile roll forming machine we exported to Mexico, it use the new type of cut and press system, the new mold can make more beautiful pitch and it controls length precision within +/- 0.5mm.

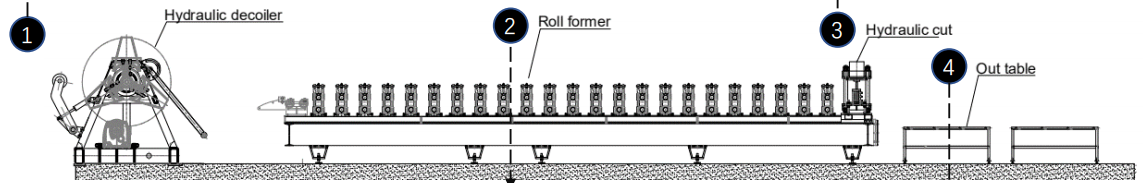

| Roof Tile Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Coil | Thickness(MM):0.3-0.8 |

| B) PPGI | ||

| C) Carbon steel Coil | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | 350 Mpa-550 Mpa | |

| Nominal forming speed(M/MIN): | 0-20 | * Or according to your requirement (Optional) |

| Forming station : | 22 stands | * According to your profile drawings (Optional) |

| Decoiler : | Manual decoiler | * Hydraulic decoiler or double head decoiler (Optional) |

| Punching system | No | * Hydraulic punching or punching press (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station or torri stand structure (Optional) |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Panasonic | * Siemens (optional) |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

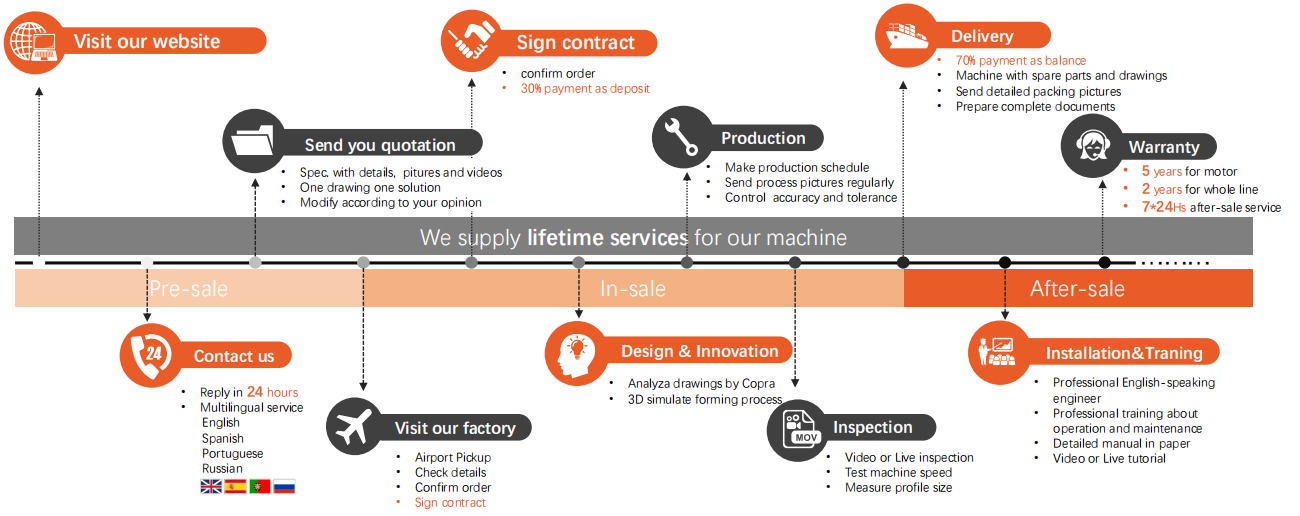

1.Q: What kinds of experience do you have in producing roof panel roll forming machine? A: Roof/wall panel (corrugated panel) roll forming machine is the most produced machine, we have many experience of this machine. We have exported to India, Spain, UK, Mexico, Peru, Argentina, Chile, Bolivia, Dubai, Egypt, Brazil, Poland, Russia, Ukraine, Kazakhstan, Bangladesh, Bulgaria, Malaysia, Turkey, Oman, Macedonia, Cyprus, USA, South Africa, Cameroon, Ghana, Nigeria etc. In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, furring channel roll forming machine, ceiling T bar roll forming machine, wall angle roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck(floor deck) roll forming machine, vigacero roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc. 2.Q: How many profiles can produce this machine? A: According to your drawing, specially the height and pitch of each wave, if they are the same, you could produce several sizes with different feeding coil width. If you want to produce one trapezoidal panel and one corrugated panel or a roof tile, we would recommend you a double layer roll forming machine to save your space and cost of machine. 3.Q: What is delivery time of trapezoidal roof panel making machine? A: 45 days to design from beginning to lubricate all rollers before shipment. 4.Q: What is your machine speed? A: Our forming speed is 0-20m/min adjustable by Yaskawa frequency changer. 5.Q: How could you control your machine’s precision and quality? A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners. 6. Q: What is your after-sales service system? A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1.Q: What kinds of experience do you have in producing roof panel roll forming machine? A: Roof/wall panel (corrugated panel) roll forming machine is the most produced machine, we have many experience of this machine. We have exported to India, Spain, UK, Mexico, Peru, Argentina, Chile, Bolivia, Dubai, Egypt, Brazil, Poland, Russia, Ukraine, Kazakhstan, Bangladesh, Bulgaria, Malaysia, Turkey, Oman, Macedonia, Cyprus, USA, South Africa, Cameroon, Ghana, Nigeria etc. In Construction Industries, we are able to manufacture more machines like main channel roll forming machine, furring channel roll forming machine, ceiling T bar roll forming machine, wall angle roll forming machine, purlin roll forming machine, drywall roll forming machine, stud roll forming machine, track roll forming machine, top hat roll forming machine, clip roll forming machine, metal deck(floor deck) roll forming machine, vigacero roll forming machine, roof/wall panel roll forming machine, roof tile roll forming machine etc. 2.Q: How many profiles can produce this machine? A: According to your drawing, specially the height and pitch of each wave, if they are the same, you could produce several sizes with different feeding coil width. If you want to produce one trapezoidal panel and one corrugated panel or a roof tile, we would recommend you a double layer roll forming machine to save your space and cost of machine. 3.Q: What is delivery time of trapezoidal roof panel making machine? A: 45 days to design from beginning to lubricate all rollers before shipment. 4.Q: What is your machine speed? A: Our forming speed is 0-20m/min adjustable by Yaskawa frequency changer. 5.Q: How could you control your machine’s precision and quality? A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners. 6. Q: What is your after-sales service system? A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.