Description

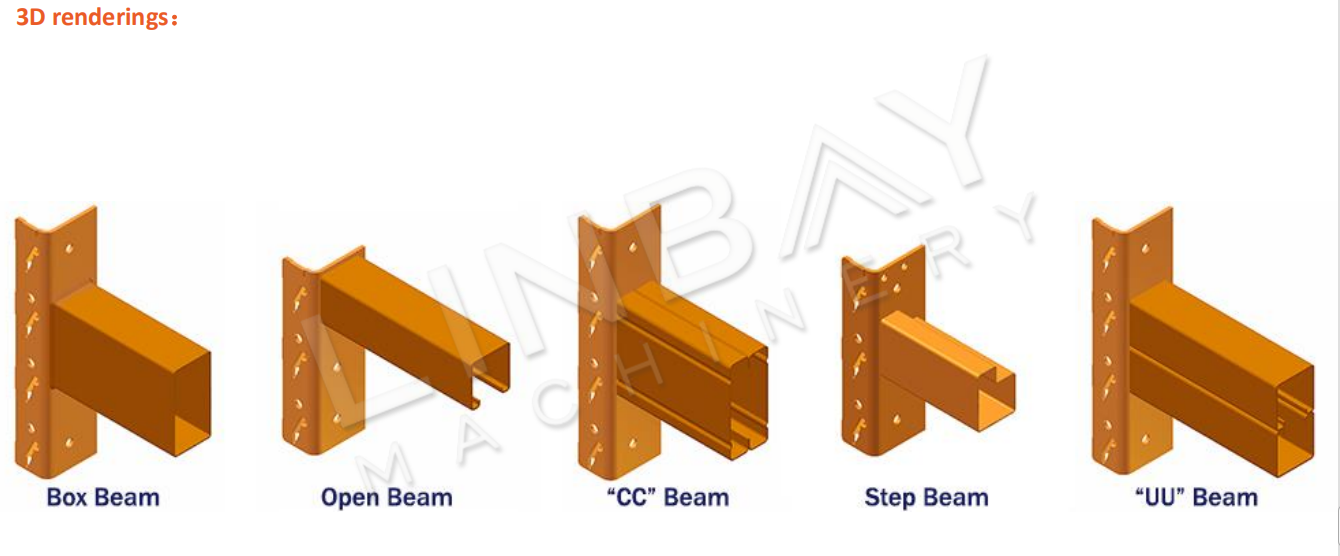

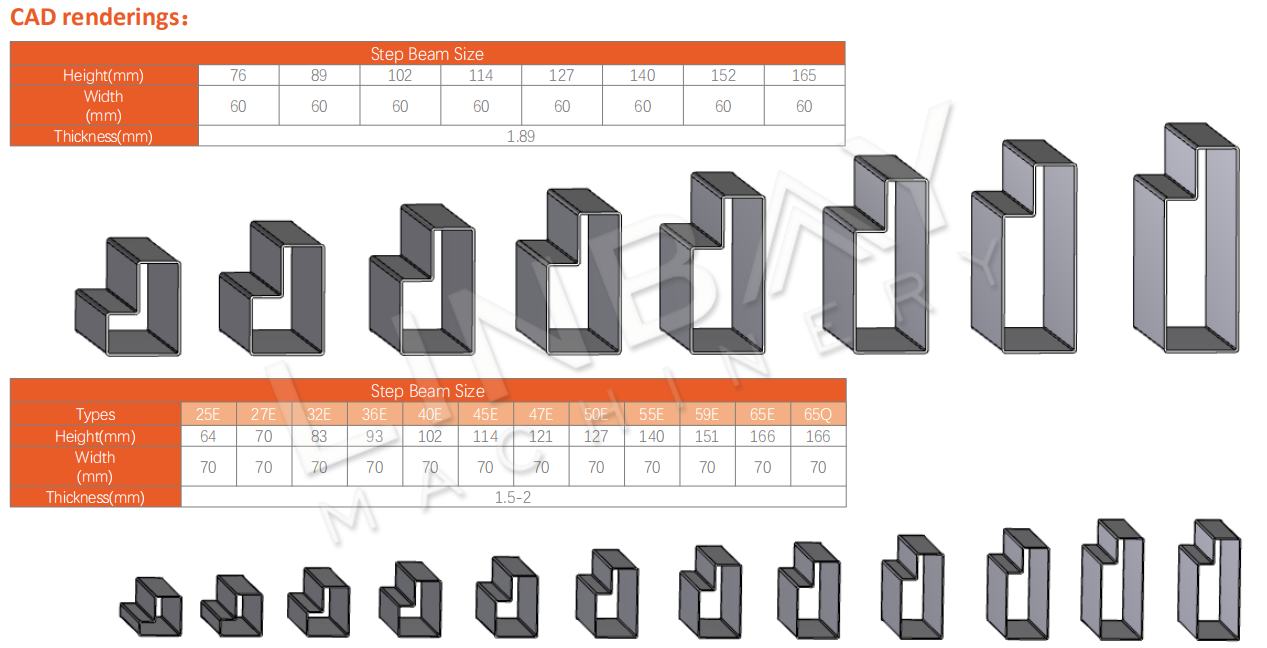

Pallet upright rack roll forming machine is widely used in producing upright frame, box beam and step beam. Our intelligent roll forming machine could make wide range of sizes using cantilever type structure, and automatically change by motors from one size to the other not only at width but also at height. The one and only step is to put your required data into our touch screen and wait for few seconds. Machinable thickness is from 1.5-3mm with raw material Cold-rolled Steel, Galvanized Coil, PPGI, Carbon steel, Stainless Steel and Aluminum. Our produced profile meet ISO, CE , FEM standards, and our machine is applied to Warehouse, supermarket, industry or home.

We have experience of exporting our pallet racking roll formers to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture more machines like Box beam roll forming machine, step beam roll forming machine and shelf panel roll forming machine etc.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Application

Real Case A

Description:

This step beam roll forming production line was installed in Mexico, 2016, using a flying saw cut and cooling system. It produces three sizes in one machine by changing sleeves manually.

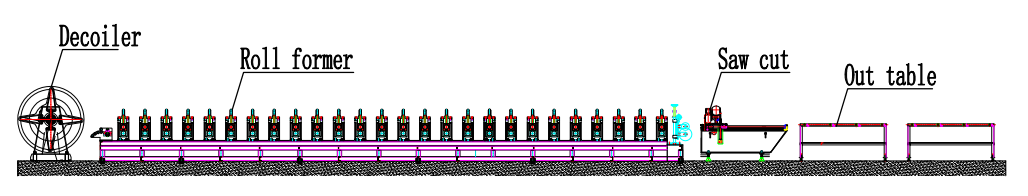

Whole Production Line of Step Beam Roll Forming Machine

Technical Specifications

| Pallet Rack Step beam Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Coil | Thickness(MM):1.5-2.0 |

| B) PPGI | ||

| C) Cold-rolled Steel | ||

| D) Stainless Steel | ||

| E) Aluminum | ||

| F) Carbon steel | ||

| Yield strength : | 250 - 350 Mpa | |

| Tensil stress : | 350 Mpa-500 Mpa | |

| Nominal forming speed(M/MIN) | 10-20 | * Or according to your requirement |

| Forming station : | 26 | * According to your profile drawings |

| Decoiler : | Hydraulic decoiler | * Double head decoiler (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Torri stands | * Cast iron stands (Optional) |

| Rollers’ material : | GCr 15 | * SKD-11 (Optional) |

| Cutting system : | Saw cut | * Flying cut (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Siemens | |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

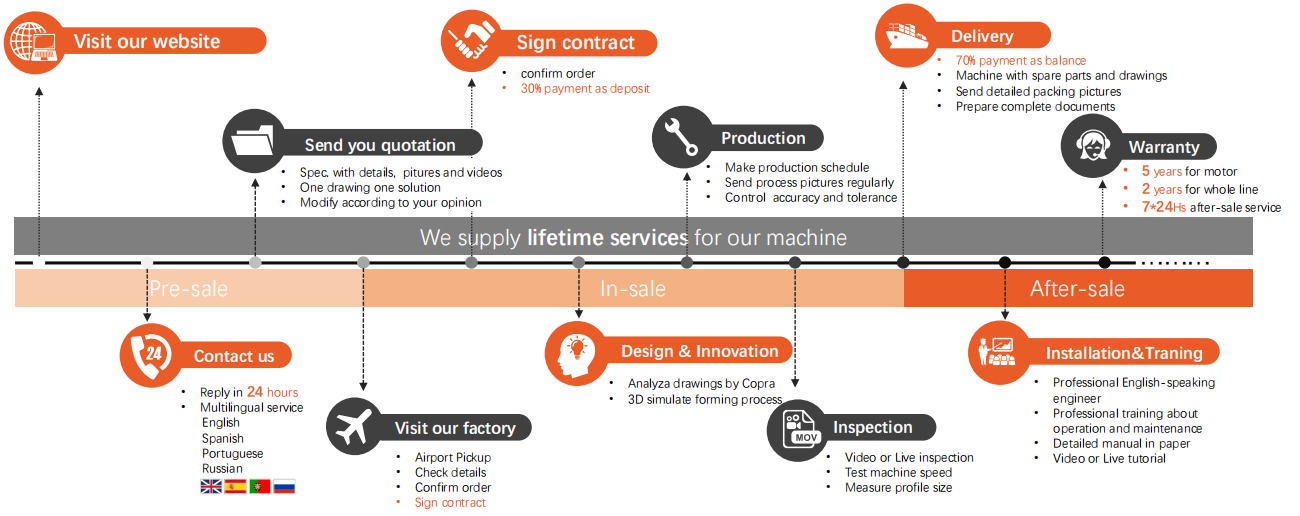

Purchase Service

Q&A

1.Q: What kinds of experience do you have in producing pallet rack roll forming machine?

A: We have exported pallet rack production line to Pakistan, Mexico, Peru, Egypt, Australia and UK etc. In warehouse pallet racking system, we are able to manufacture Upright beam roll forming machine, Box beam roll forming machine, step beam roll forming machine and shelf panel roll forming machine etc. We are confident to solve your shelve problem.

2.Q: How many sizes can produce this machine?

A: We adopt cast iron structure or cantilever structure with automatic width-change and height-change system. One machine could produce several profiles, we would check your profile drawings to meet your needs. We are dedicated to provide cost-effective solutions.

3.Q: What is delivery time of warehouse shelf roll forming machine?

A: 80 days to 100 days depends on your drawing.

4.Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. In addition, considering the complicated punch holes, we recommend that you use a separate punch line to increase production speed, and it’s more cost-effective.

5.Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6.Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.