Description

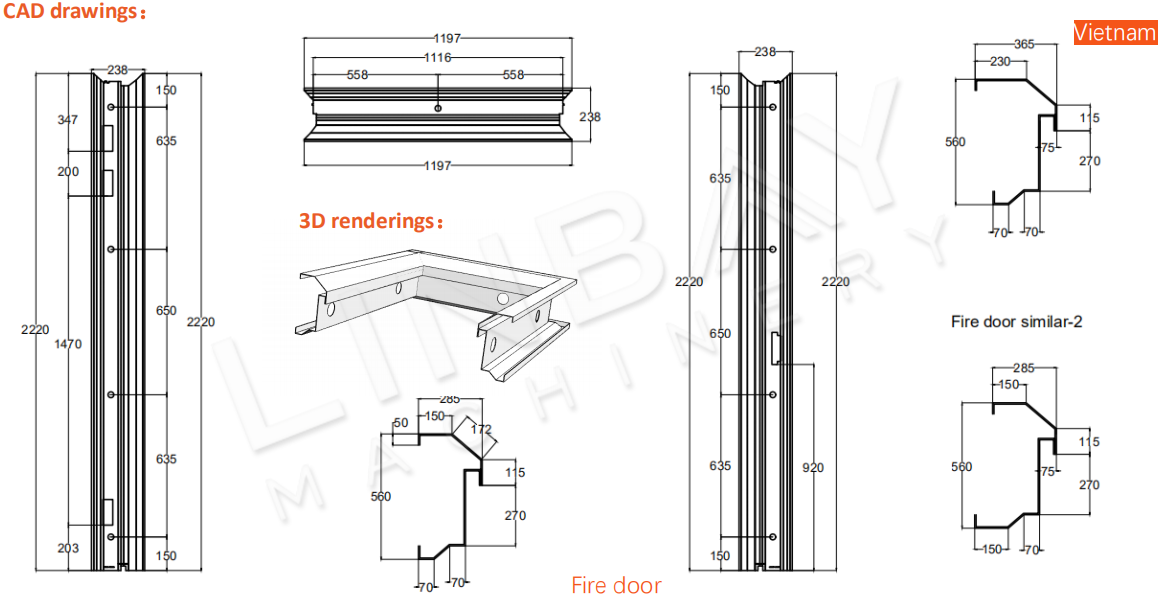

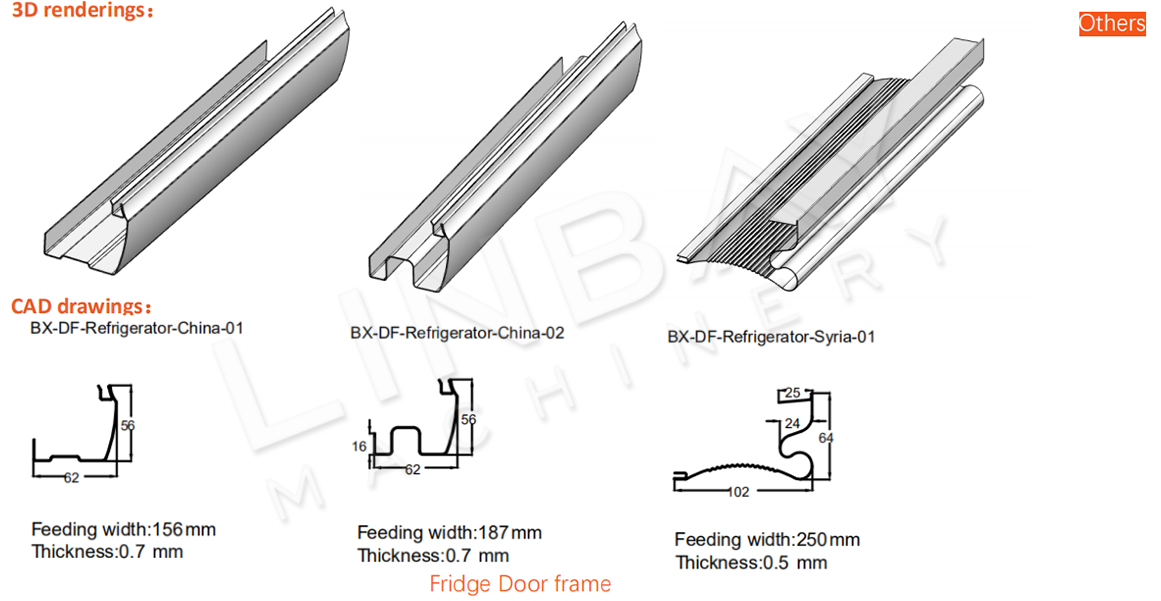

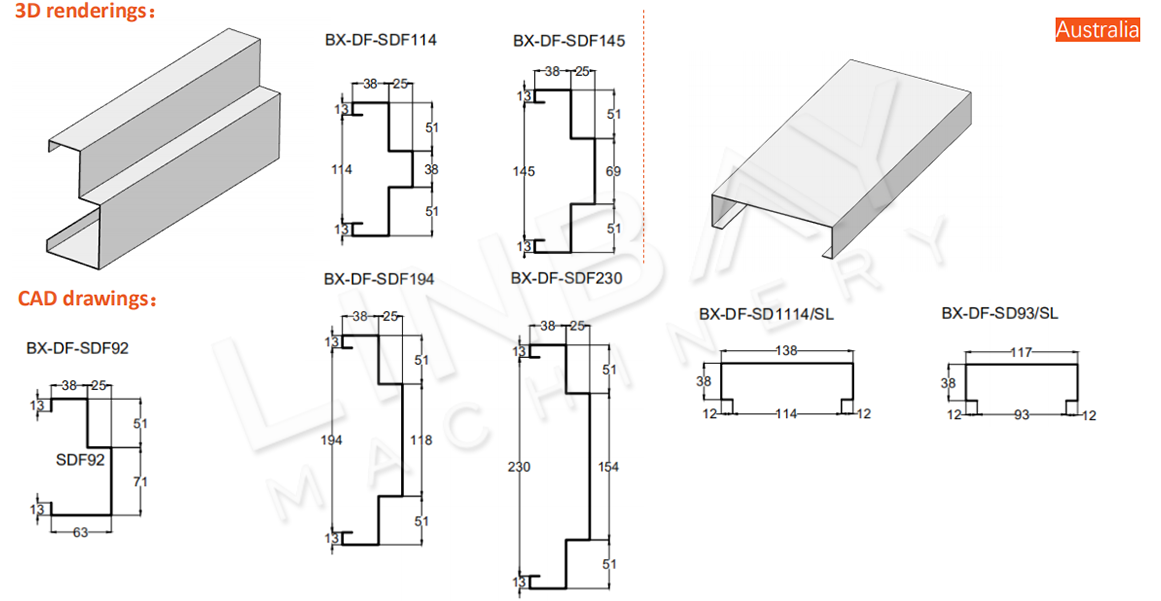

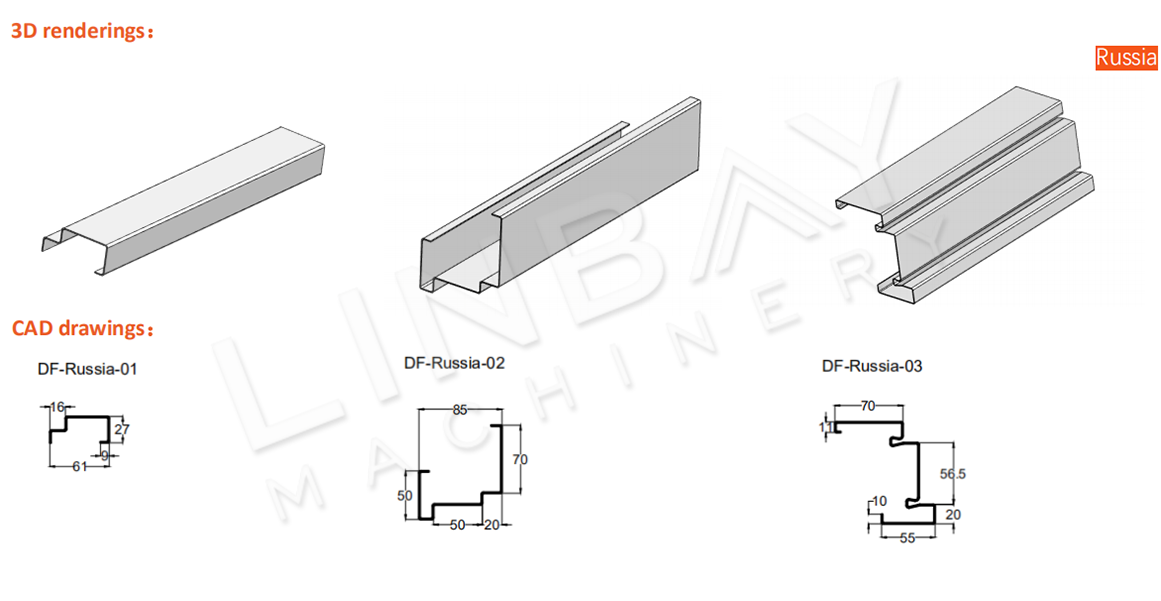

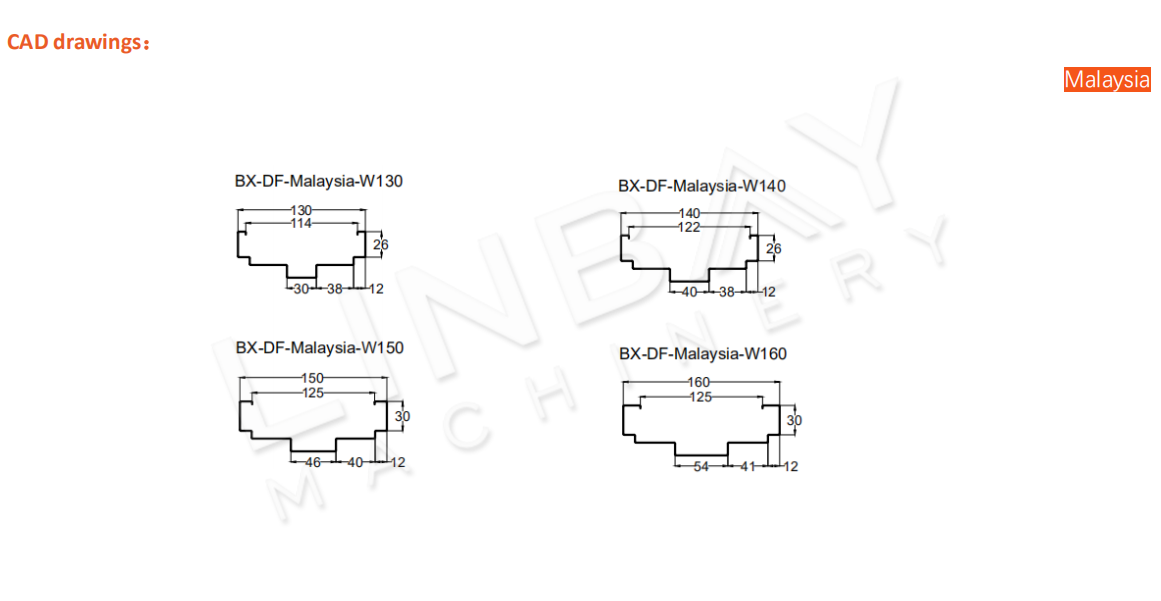

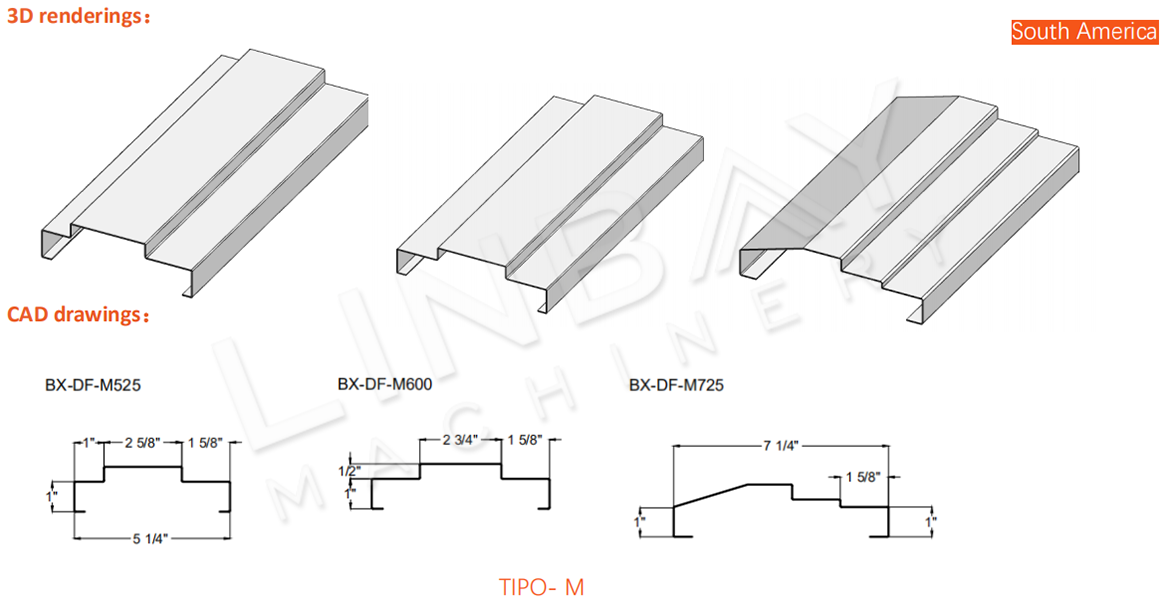

Linbay Door frame roll forming machine is suitable for any kind of metal door frame, for example: fire rated door, safety door, sliding door, industry door and interior door etc. Machinable steel material can be zinc-coated steel, galvanized steel, stainless steel. Galvanized door frame machine is more popular during our customers. Thickness range could be 0.6- 1.2mm or 1.2-1.6mm(heavy duty) and Gauge 14/16/18. Here are some profiles widely used of door frame as reference: ⚫ Double rabbet door frame ⚫ Door rabbet mullion/Transom ⚫ Single rabbet door frame ⚫ Single rabbet mullion/Transom ⚫ Cased openining door frame ⚫ Double egress door frame ⚫ Drywall door frame ⚫ Shadow line door frame ⚫ Standard DELUXE door frame ⚫ Kerfed door frame Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.Profile Drawings

Shapes for Doors

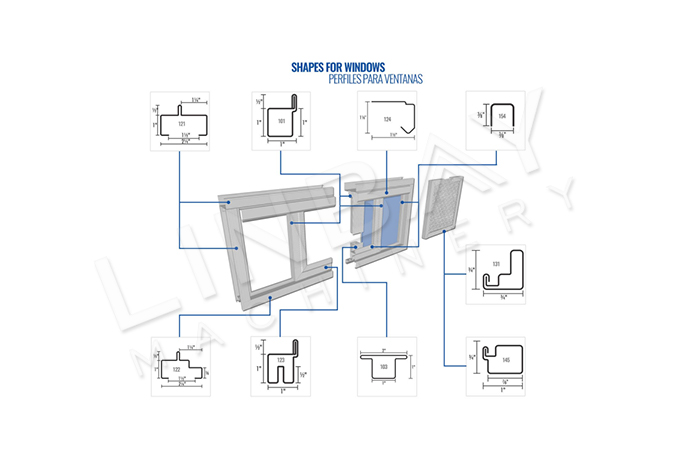

Shapes for Windows

Application

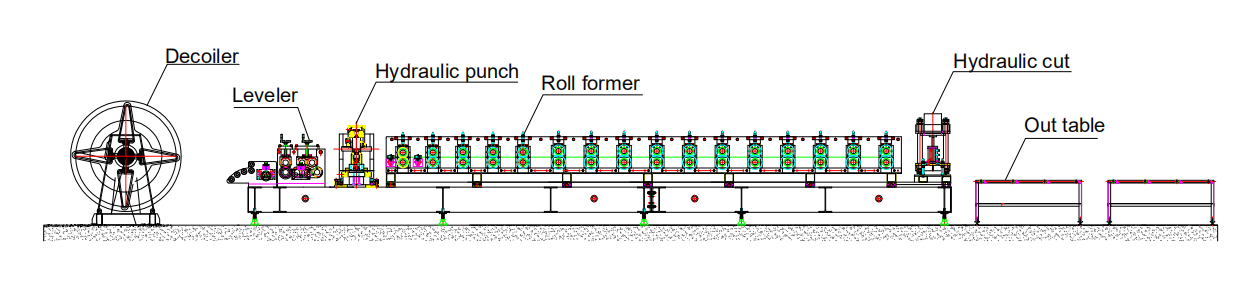

Real Case A - Door frame roll forming machine

Real Case A - Door frame roll forming machine  Description: This door frame line was produced on 2017/07/04 to Mexico, profile type: single rabate door frame with two width size: 110mm and 120mm. Single rabate profile is very popular in Latino America. Real Case B - Window frame roll forming machine

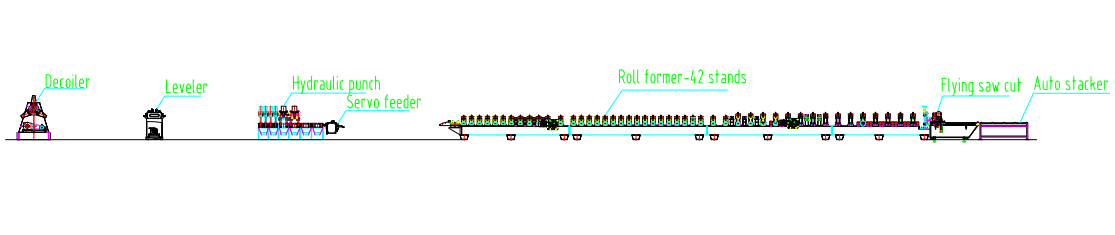

Description: This door frame line was produced on 2017/07/04 to Mexico, profile type: single rabate door frame with two width size: 110mm and 120mm. Single rabate profile is very popular in Latino America. Real Case B - Window frame roll forming machine  Description: This window frame roll forming machine was exported to India TATA Steel Group on 2018/11/27. This line has a classified profile drawing specially designed by TATA Group and it produced by our 42 stands roll former. It's amazing.

Description: This window frame roll forming machine was exported to India TATA Steel Group on 2018/11/27. This line has a classified profile drawing specially designed by TATA Group and it produced by our 42 stands roll former. It's amazing. Whole Production Line of Door Window Frame Roll Forming Machine

Technical Specifications

| Door Frame Roll Forming Machine | ||

| Machinable Material : | A) Galvanised Steel | Thickness(MM):0.6-1.2, 1.2-1.6, Gauge14/16/18 |

| B) Stainless Steel | ||

| C) Zinc-coated steel | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | 350 Mpa-550 Mpa | |

| Nominal forming speed(M/MIN) | 0-20 | * Or according to your requirement |

| Forming stands : | 17-20 stands | * According to your profile drawings |

| Decoiler : | Manual decoiler | * Hydraulic decoiler or double head decoiler(Optional) |

| Punching system | Hydraulic punching station | * Punching press (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station Or torri stand structure (Optional) |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

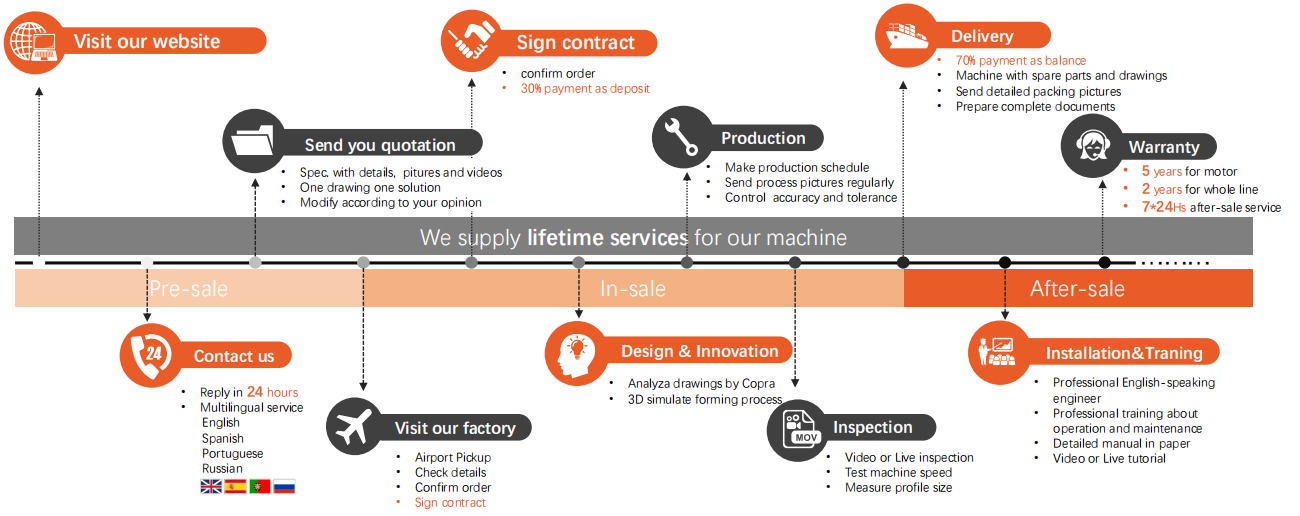

Purchase Service