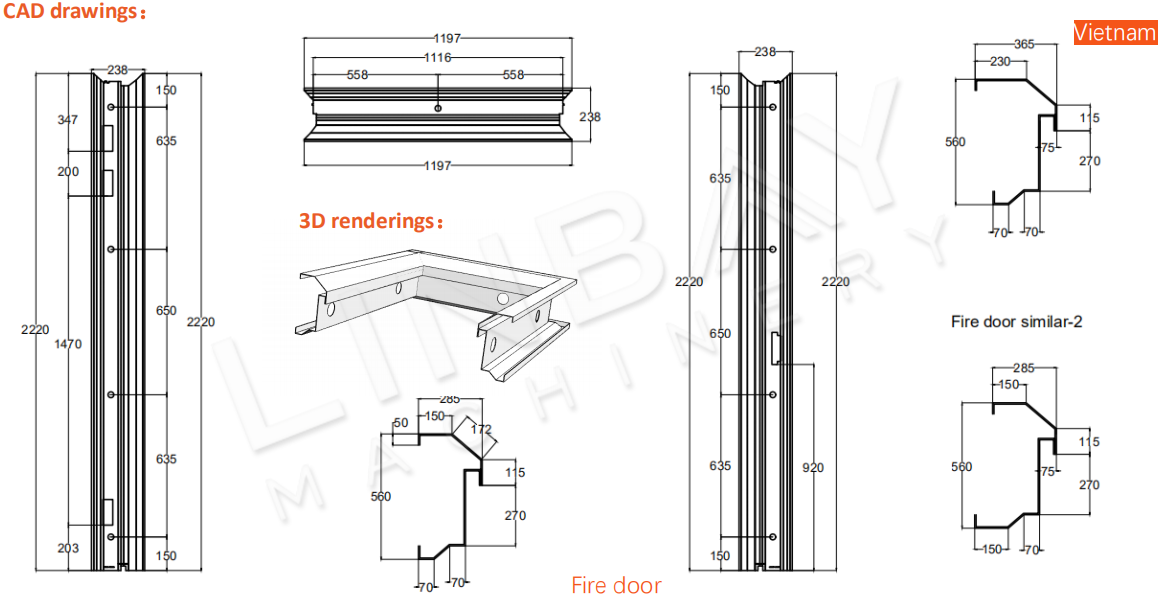

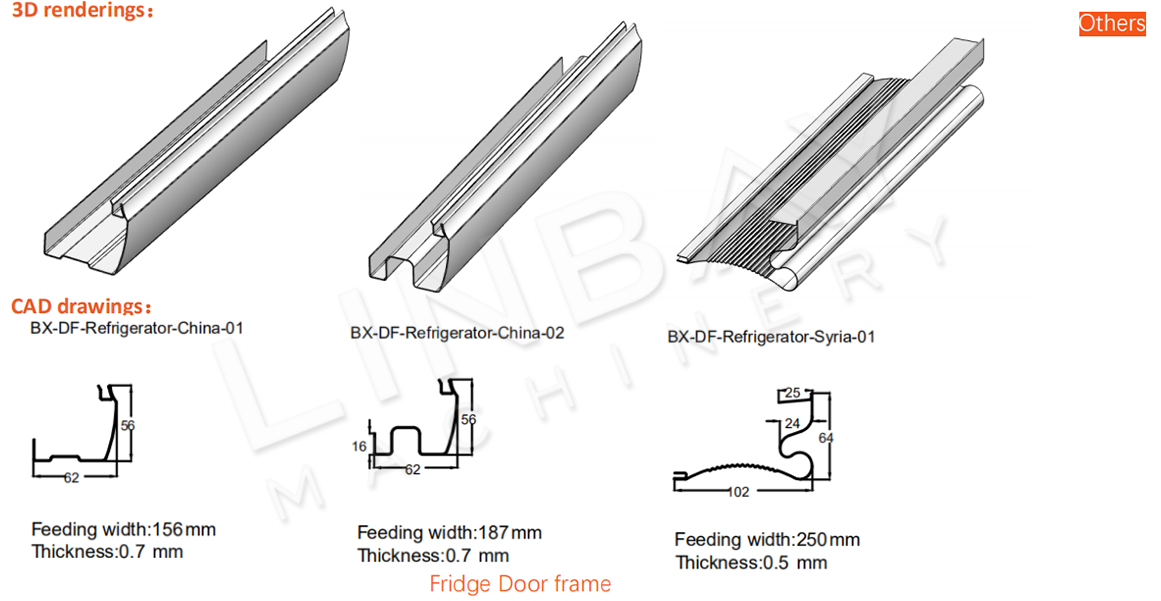

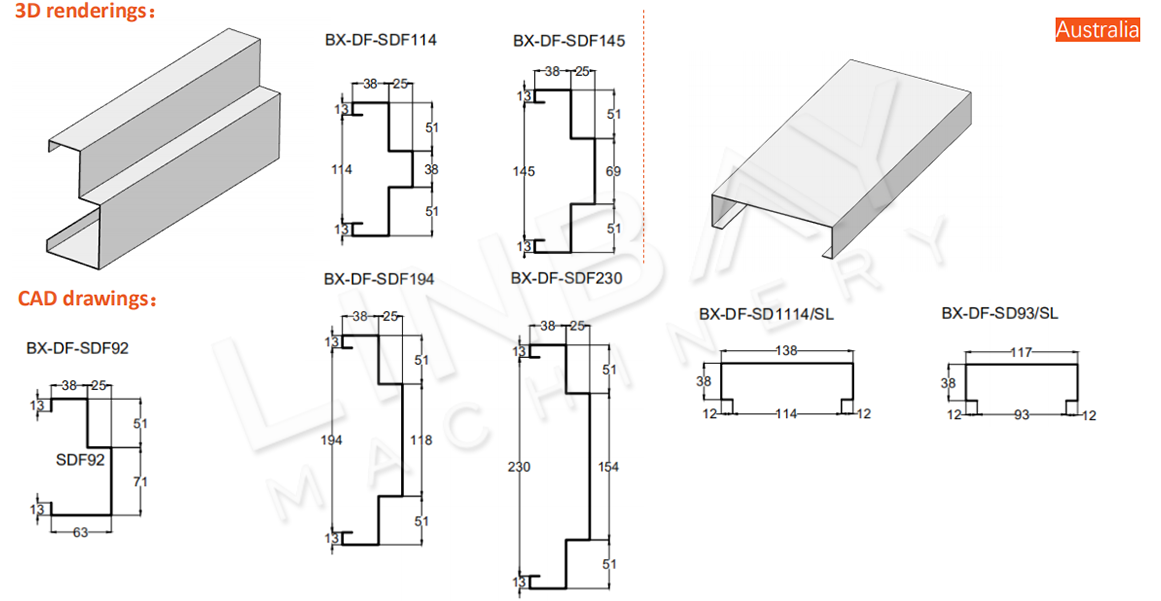

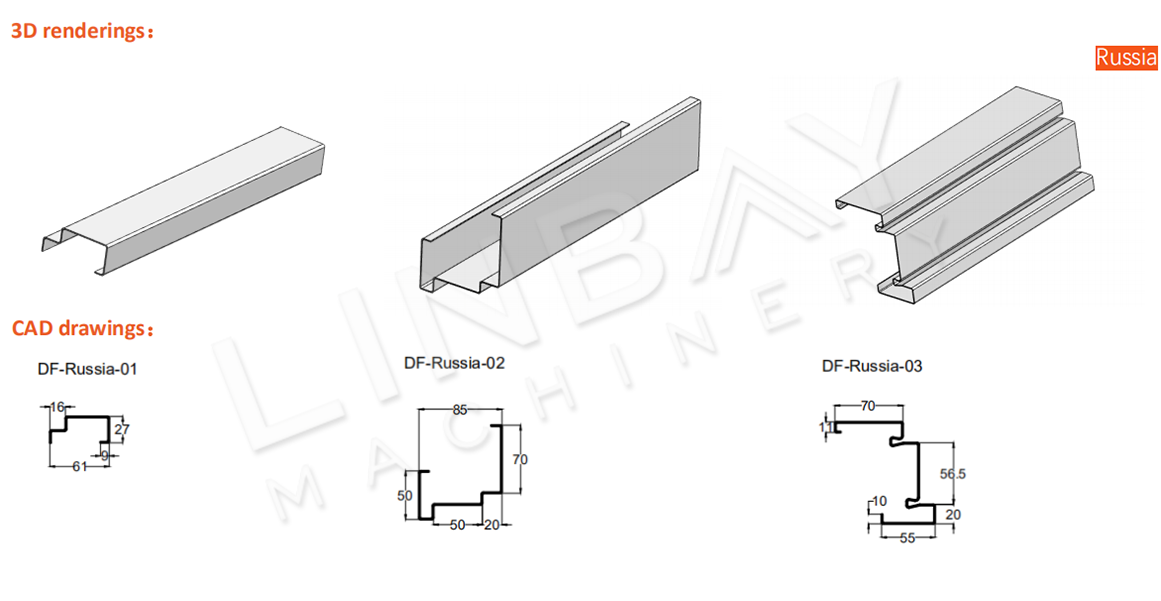

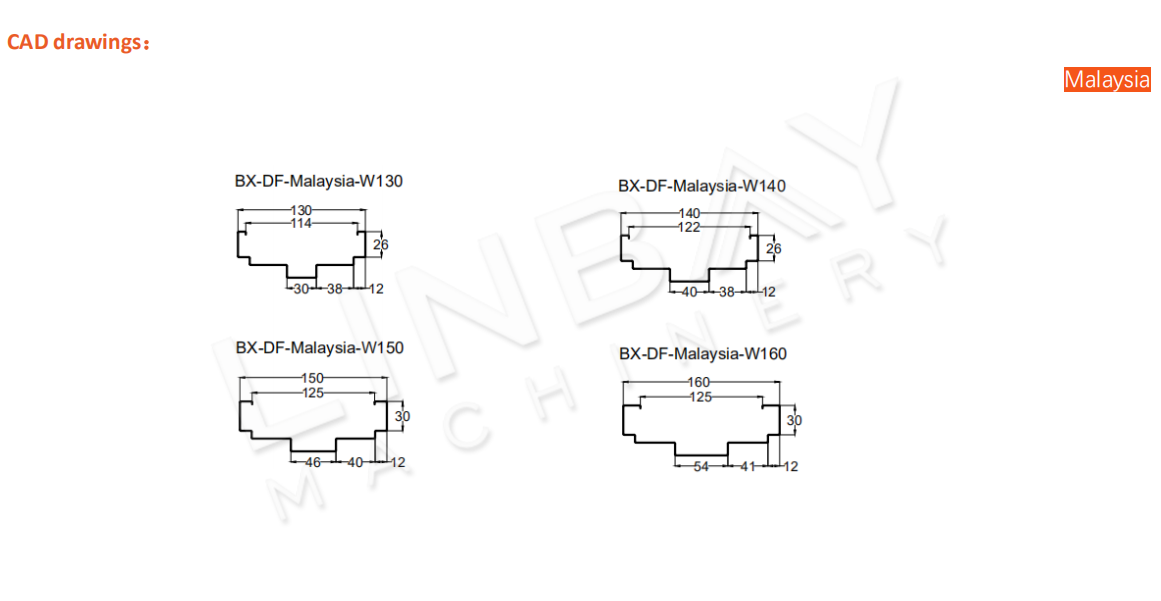

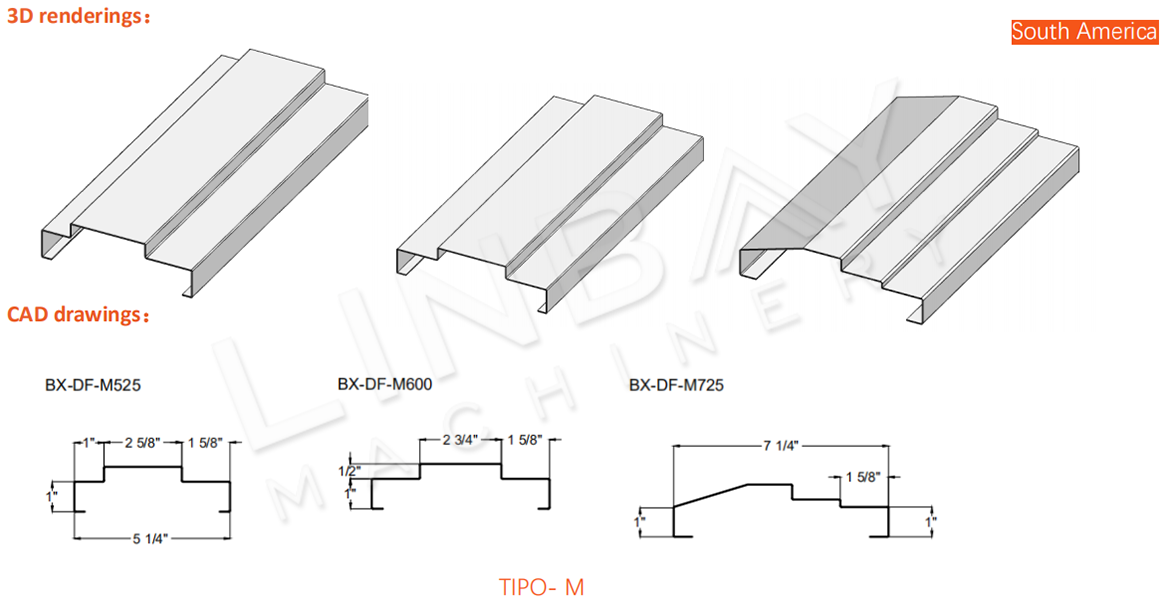

Linbay Door frame roll forming machine is suitable for any kind of metal door frame, for example: fire rated door, safety door, sliding door, industry door and interior door etc. Machinable steel material can be zinc-coated steel, galvanized steel, stainless steel. Galvanized door frame machine is more popular during our customers. Thickness range could be 0.6- 1.2mm or 1.2-1.6mm(heavy duty) and Gauge 14/16/18. Here are some profiles widely used of door frame as reference: ⚫ Double rabbet door frame ⚫ Door rabbet mullion/Transom ⚫ Single rabbet door frame ⚫ Single rabbet mullion/Transom ⚫ Cased openining door frame ⚫ Double egress door frame ⚫ Drywall door frame ⚫ Shadow line door frame ⚫ Standard DELUXE door frame ⚫ Kerfed door frame Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Linbay Door frame roll forming machine is suitable for any kind of metal door frame, for example: fire rated door, safety door, sliding door, industry door and interior door etc. Machinable steel material can be zinc-coated steel, galvanized steel, stainless steel. Galvanized door frame machine is more popular during our customers. Thickness range could be 0.6- 1.2mm or 1.2-1.6mm(heavy duty) and Gauge 14/16/18. Here are some profiles widely used of door frame as reference: ⚫ Double rabbet door frame ⚫ Door rabbet mullion/Transom ⚫ Single rabbet door frame ⚫ Single rabbet mullion/Transom ⚫ Cased openining door frame ⚫ Double egress door frame ⚫ Drywall door frame ⚫ Shadow line door frame ⚫ Standard DELUXE door frame ⚫ Kerfed door frame Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.

Real Case A - Door frame roll forming machine

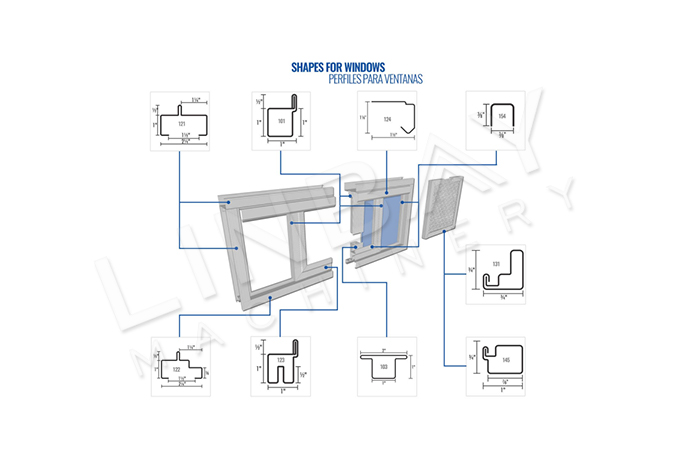

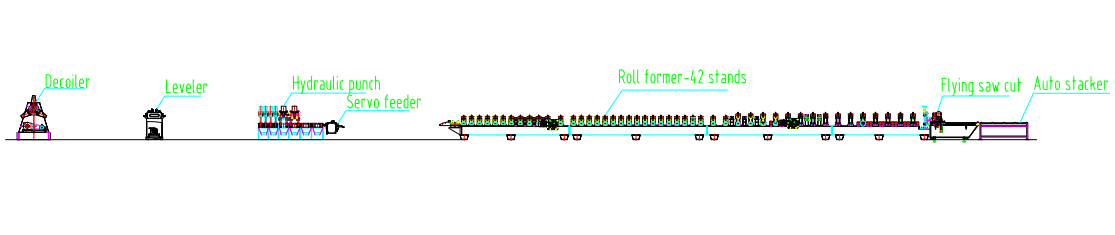

Real Case A - Door frame roll forming machine  Description: This door frame line was produced on 2017/07/04 to Mexico, profile type: single rabate door frame with two width size: 110mm and 120mm. Single rabate profile is very popular in Latino America. Real Case B - Window frame roll forming machine

Description: This door frame line was produced on 2017/07/04 to Mexico, profile type: single rabate door frame with two width size: 110mm and 120mm. Single rabate profile is very popular in Latino America. Real Case B - Window frame roll forming machine  Description: This window frame roll forming machine was exported to India TATA Steel Group on 2018/11/27. This line has a classified profile drawing specially designed by TATA Group and it produced by our 42 stands roll former. It's amazing.

Description: This window frame roll forming machine was exported to India TATA Steel Group on 2018/11/27. This line has a classified profile drawing specially designed by TATA Group and it produced by our 42 stands roll former. It's amazing.

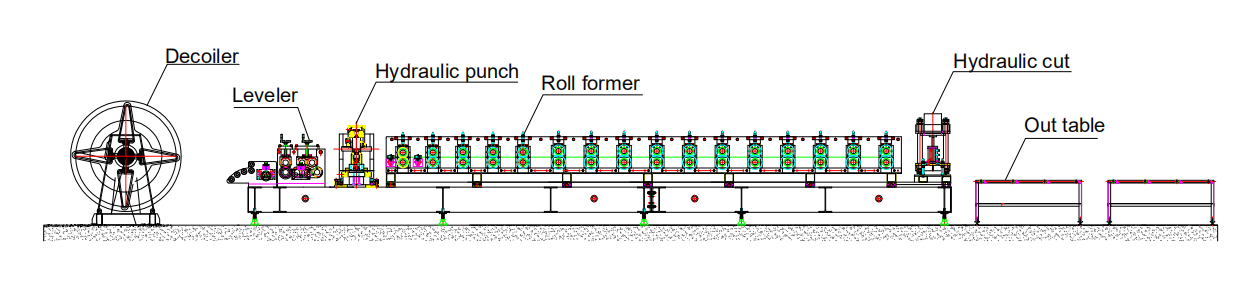

| Door Frame Roll Forming Machine | ||

| Machinable Material : | A) Galvanised Steel | Thickness(MM):0.6-1.2, 1.2-1.6, Gauge14/16/18 |

| B) Stainless Steel | ||

| C) Zinc-coated steel | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | 350 Mpa-550 Mpa | |

| Nominal forming speed(M/MIN) | 0-20 | * Or according to your requirement |

| Forming stands : | 17-20 stands | * According to your profile drawings |

| Decoiler : | Manual decoiler | * Hydraulic decoiler or double head decoiler(Optional) |

| Punching system | Hydraulic punching station | * Punching press (Optional) |

| Main machine motor brand : | Sino-Germany Brand | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station Or torri stand structure (Optional) |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (optional) |

| Frequency changer brand : | Yaskawa | * Siemens (optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

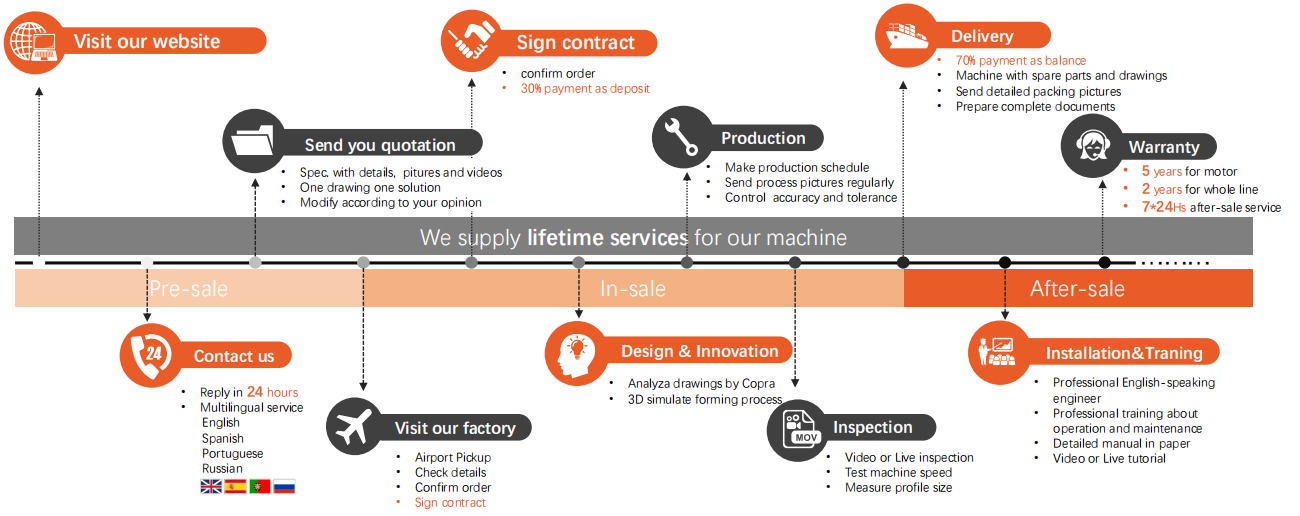

1. Q: What kinds of experience do you have in producing door frame roll forming machine? A: We have many experience in door frame machine, all of our customers are located all over the world and are very satisfied due to our excellent price-quality ratio such as Australia, USA, Ecuador, Ethiopia, Russia, India, Iran, Vietnam, Argentina, Mexico etc. Now the biggest customer we are serving is TATA STEEL INDIA, we’ve sold 8 lines on 2018, and right now we are assembling other 5 lines for them. 2. Q: What are the advantages do you have? A: We have our own factory, we are 100% manufacturer, so we could easily control the delivery time and machine quality, offering you the best Chinese after-sales service. Besides, our innovative team is well educated with bachelor degree, who could also talk in English, realizing smooth communication when he comes to install your machine. He has more than 20 years of experience and could solve any problem alone during his work. Next, our sales team will always takes care of your every needs to make a one-to-one solution, giving you professional idea and suggestion to let you get an affordable and practical producing line. Linbay is always your best choice of roll forming machine. 3. Q: What is the delivery time of door frame roll forming machine? A: We need to take 40-60 days from machine design to assemble it. And the delivery time should be confirmed after checking door frame drawing. 4. Q: What is the machine speed? A: Normally line speed is around 0-15m/min, the working speed depends on your perforation drawing as well. 5. Q: How could you control your machine’s precision and quality? A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners. 6. Q: What is your after-sales service system? A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

1. Q: What kinds of experience do you have in producing door frame roll forming machine? A: We have many experience in door frame machine, all of our customers are located all over the world and are very satisfied due to our excellent price-quality ratio such as Australia, USA, Ecuador, Ethiopia, Russia, India, Iran, Vietnam, Argentina, Mexico etc. Now the biggest customer we are serving is TATA STEEL INDIA, we’ve sold 8 lines on 2018, and right now we are assembling other 5 lines for them. 2. Q: What are the advantages do you have? A: We have our own factory, we are 100% manufacturer, so we could easily control the delivery time and machine quality, offering you the best Chinese after-sales service. Besides, our innovative team is well educated with bachelor degree, who could also talk in English, realizing smooth communication when he comes to install your machine. He has more than 20 years of experience and could solve any problem alone during his work. Next, our sales team will always takes care of your every needs to make a one-to-one solution, giving you professional idea and suggestion to let you get an affordable and practical producing line. Linbay is always your best choice of roll forming machine. 3. Q: What is the delivery time of door frame roll forming machine? A: We need to take 40-60 days from machine design to assemble it. And the delivery time should be confirmed after checking door frame drawing. 4. Q: What is the machine speed? A: Normally line speed is around 0-15m/min, the working speed depends on your perforation drawing as well. 5. Q: How could you control your machine’s precision and quality? A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners. 6. Q: What is your after-sales service system? A: We don’t hesitate to give you a 2 years warranty period for whole lines, 5 years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.