Description

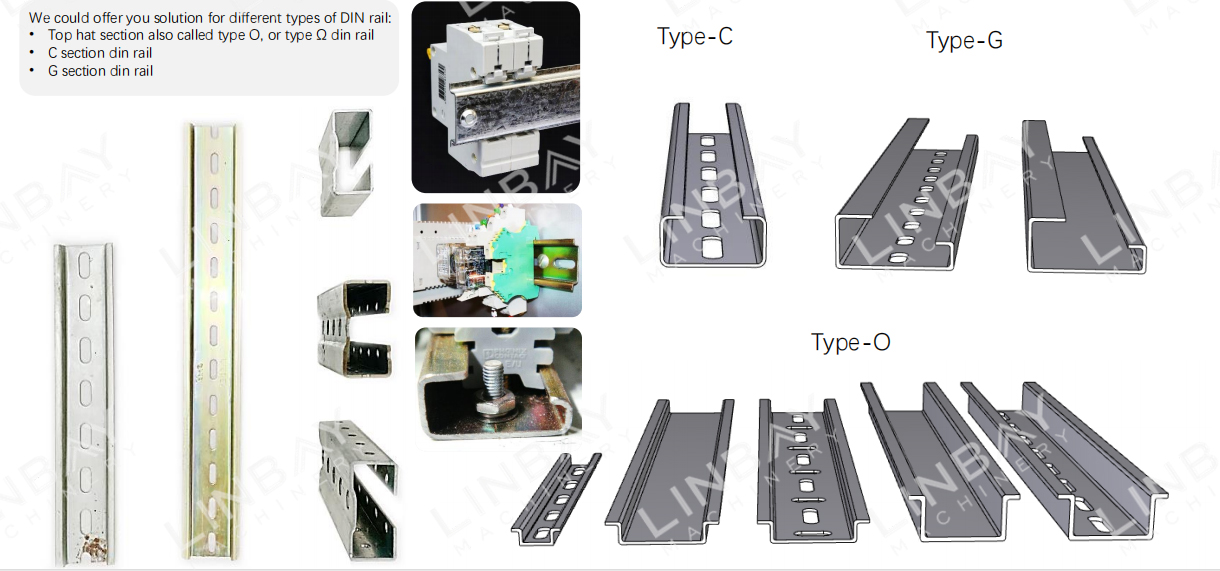

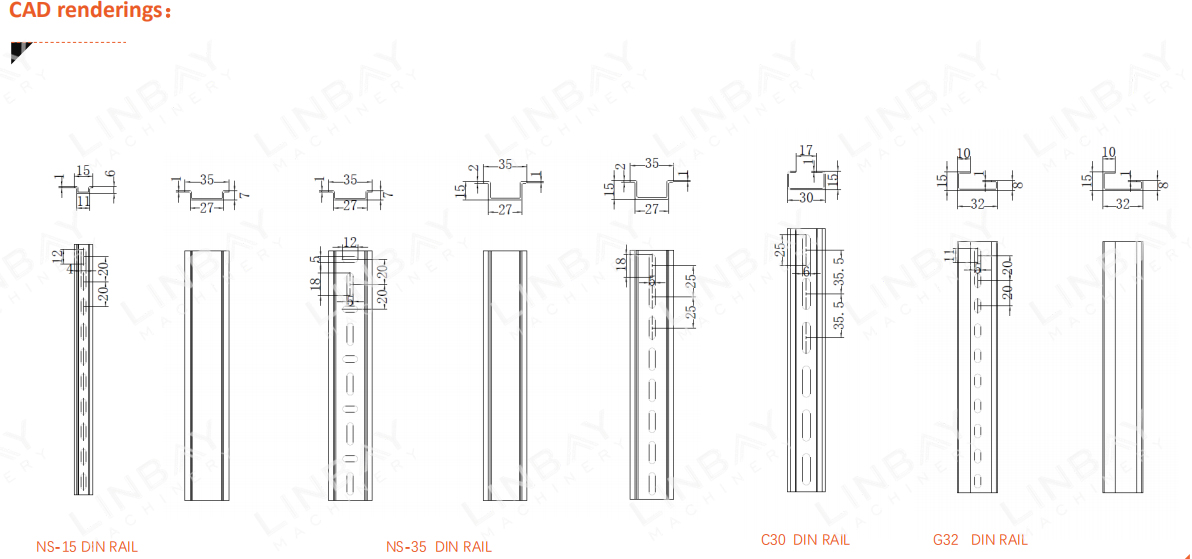

Din rail roll forming machine is to produce DIN rail for electrical cabinet, which is widely used for mounting circuit breakers and industrial control equipment inside equipment racks. Machinable materials usually are Zinc-plated steel, Aluminum, Stainless steel etc with sheet thickness 1 - 1.5mm. Normally Din rail roll forming machine produce one size, but in our Argentine case we offer a double row roll forming machine, it could be more economic and competitive when you need produce two or more size, also we could make triple-row if you have one more size. Line working speed could reach 30m/min. Our machine could produce DIN rails meet different standard and series in different countries: ⚫ IEC / EN 60715 - 35×7.5 ⚫ IEC / EN 60715 - 35×15 ⚫ EN 50022 in Europe ⚫ BS 5585 or BS 5584 in British ⚫ DIN 46277 in German ⚫ AS 2756.1997 in Australia ⚫ USA series: TS35, TS15 ⚫ Argentina series: NS35 ⚫ C section series: C20, C30, C40, C50 ⚫ G section series: EN 50035 G32 Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.Application

3D-Drawing

Real Case A

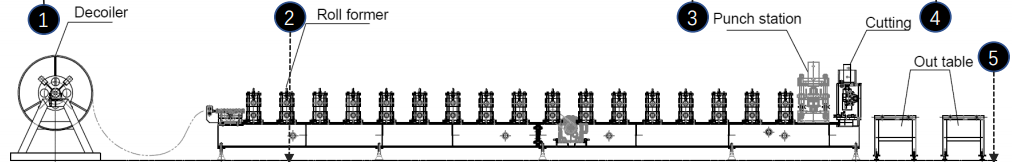

Real Case A  Description: This DIN rail roll forming machine could make 4 types of NS35 Series Din rail, very economic and competitive. In this case, we use a double row structure to produce 2 different sizes, no need to change any parts of machine, everyone could operate it with no difficulty. We could also offer you a faster line, whose line speed can reach 30m/min.

Description: This DIN rail roll forming machine could make 4 types of NS35 Series Din rail, very economic and competitive. In this case, we use a double row structure to produce 2 different sizes, no need to change any parts of machine, everyone could operate it with no difficulty. We could also offer you a faster line, whose line speed can reach 30m/min. Whole Production Line of Din Rail Roll Forming Machine

Technical Specifications

| DIN Rail Roll Forming Machine | ||

| Item | Specifications | Optional performance |

| Machinable Material : | A) Zinc-plated steel | Thickness(MM): 1-1.5 |

| B) Aluminum | ||

| C) Stainless steel | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | G250 Mpa-G550 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press (Optional) |

| Forming station : | 10 stands | * According to your profile drawings |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Cast Iron (Optional) |

| Forming speed: | 10-20 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | Steel #45 | * GCr 15 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

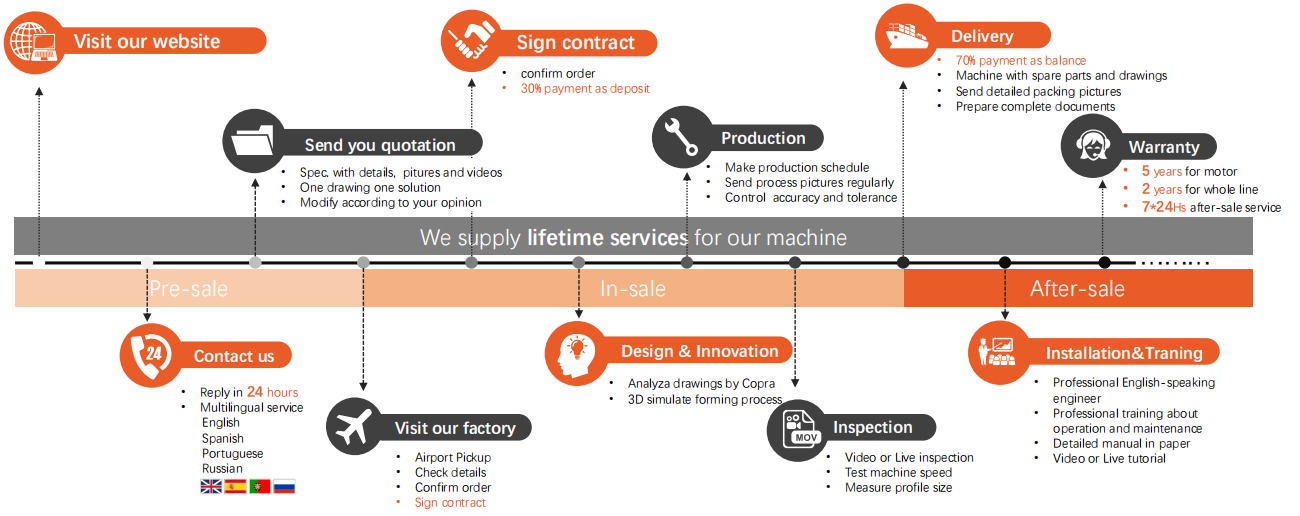

Purchase Service