Description

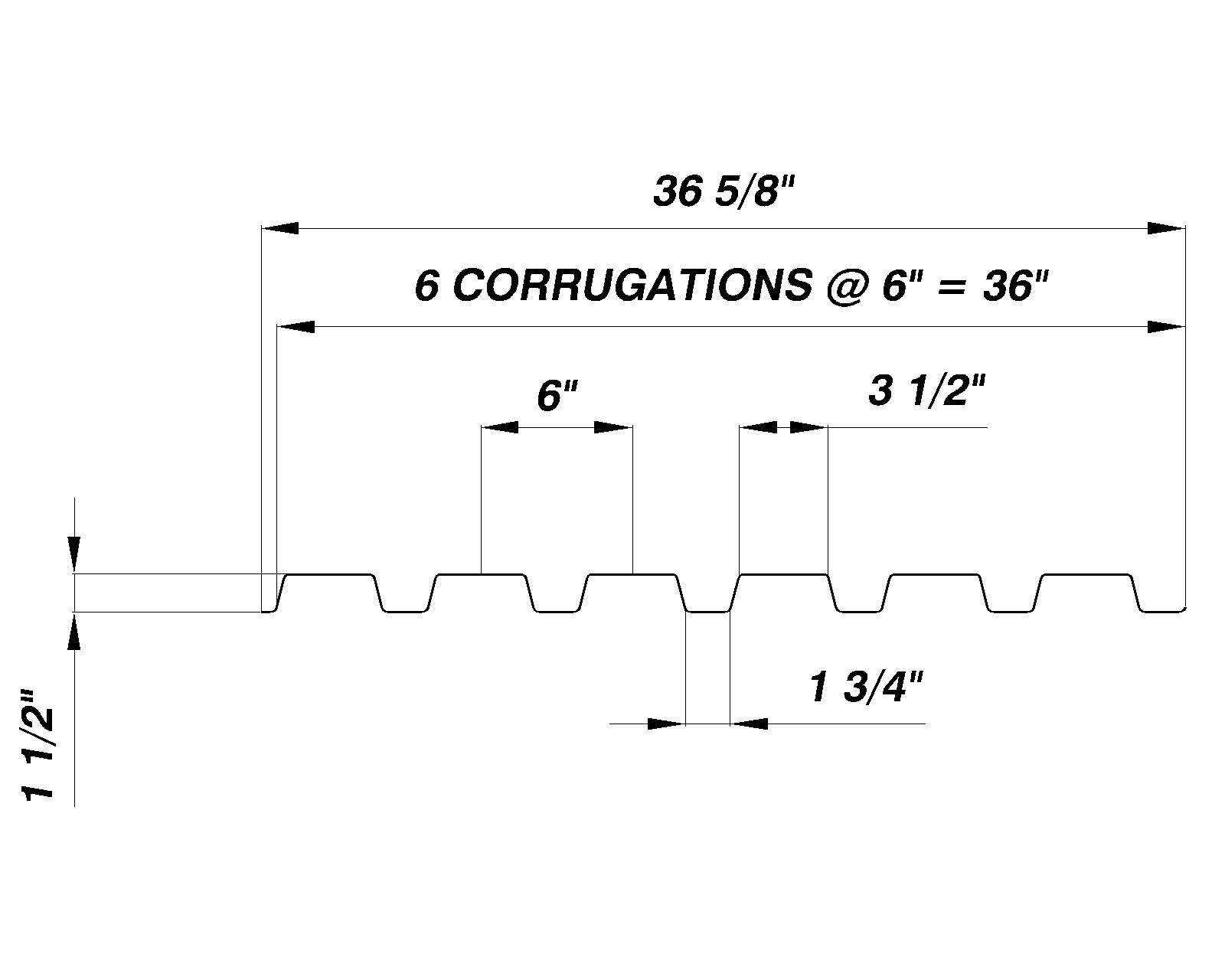

Linbay Machinery is a leading producer of steel deck roll forming machines. We had experience of making roll forming machine of B deck. B Deck is a conventional metal deck profile in the United States which meets recent North American Specification(ANSI standard). B Deck is usuallly produced using 0.8-1.5mm(Gauge 22, Gauge 20, Gauge 18, Gauge 16) thickness galvanized steel. Our roll forming machine uses 28 forming stations to make perfect B Deck profile, if the yield strength of steel material is higher than 345MPa, it will need more forming stations. Our machine doby is sturdy and durable. The machine body is about 20 meters long, it can be disassembled into 3-4 sections for easy transportation and installation. The roll forming part has two 22KW motors, Siemens brand, powerful during production. Shafts φ85mm, forming rollers GCr15, chromed plated surface is bright and not easy to rust, and will not cause scrathes on the surface of galvanized steel. The exquisite processing technology makes the machine more smooth in operation and it has a longer service life. The profile produced by our roll forming machine is straight and horizontal, with high accuracy in flatness and distortion, and the length accuracy can be controlled within plus or minus 1mm. Linbay Machinery can also make other types of metal deck roll forming machine, for information on any of our roll forming machines please contact with us.Profile Drawings

Whole Production Line of Metal Deck Roll Forming Machine

Technical Specifications

| Metal Deck Roll Forming Machine | ||

| Machinable Material : | Galvanized Coil | Thickness(MM):0.8-1.5 |

| Yield strength : | 200 - 350 Mpa | |

| Nominal forming speed(M/MIN): | 0-20 | * Or according to your requirement (Optional) |

| Forming station : | 28 stands | * According to your steel material |

| Decoiler : | Manual decoiler | * Hydraulic decoiler 10 tons (Optional) |

| Main machine motor brand : | Simens Brand | |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Wall panel station | * Forged Iron station (Optional) |

| Rollers’ material : | GCr15 | * Cr 12 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Siemens | |

| Power supply : | 380V 50Hz | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

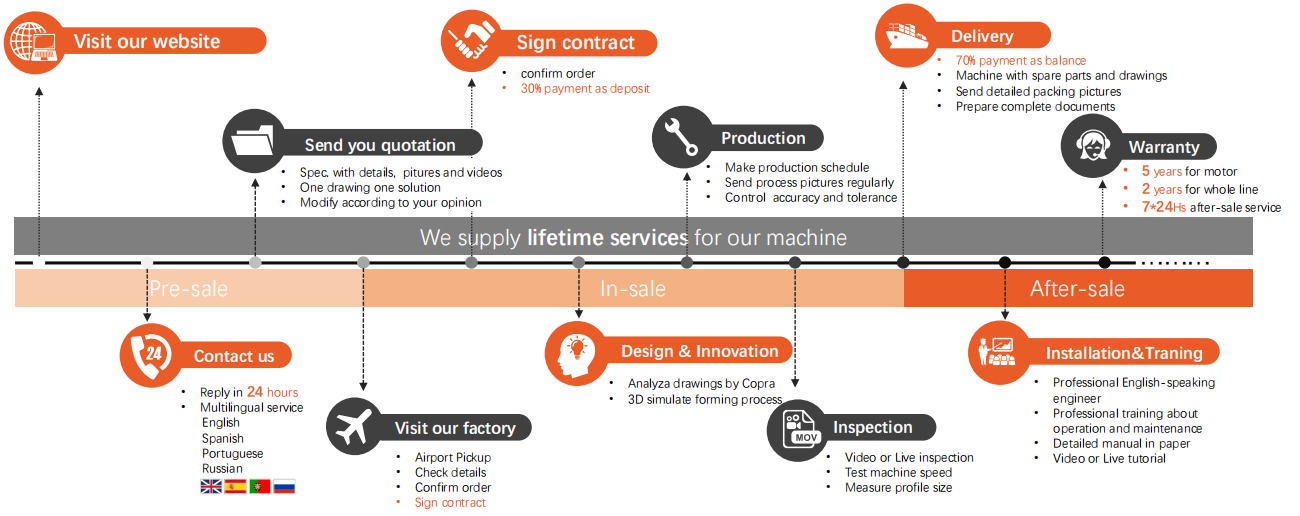

Purchase Service