Description

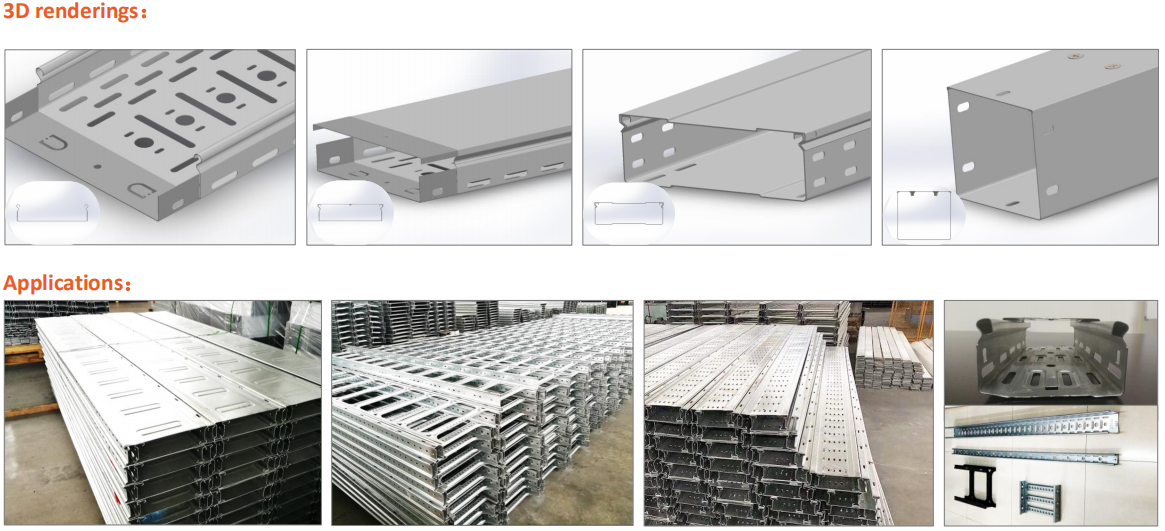

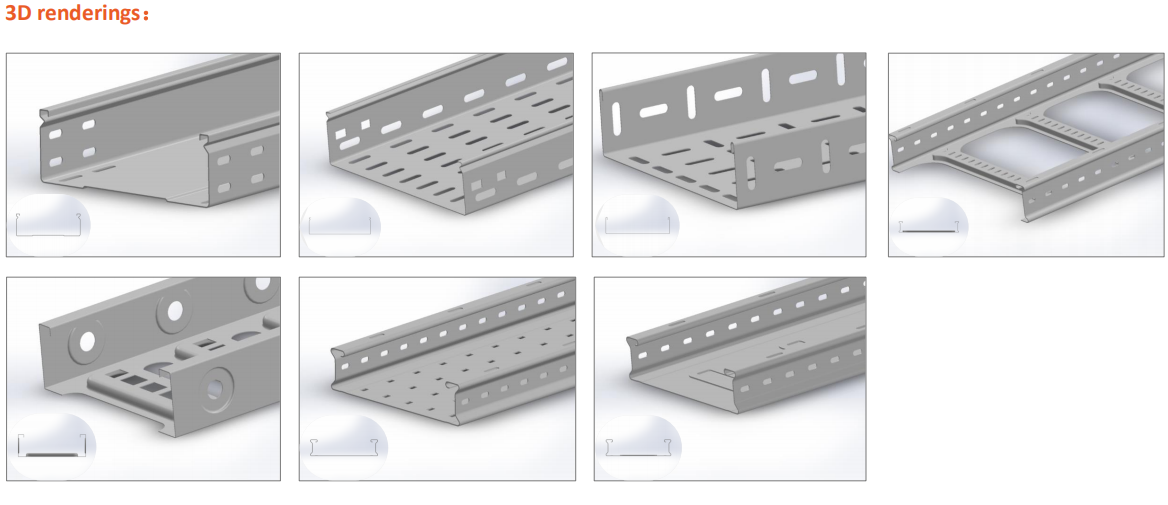

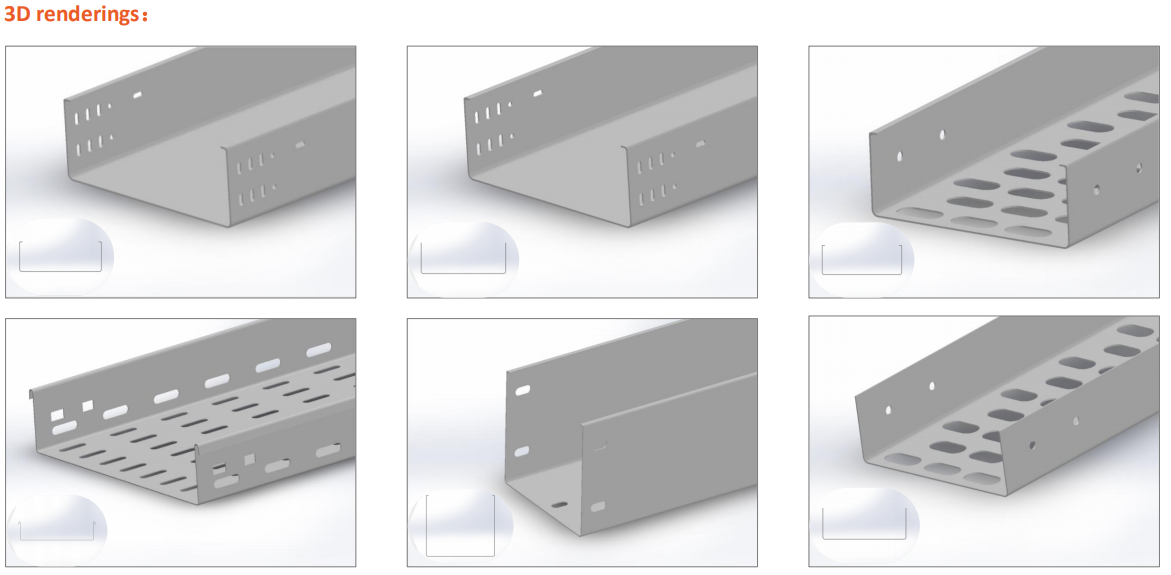

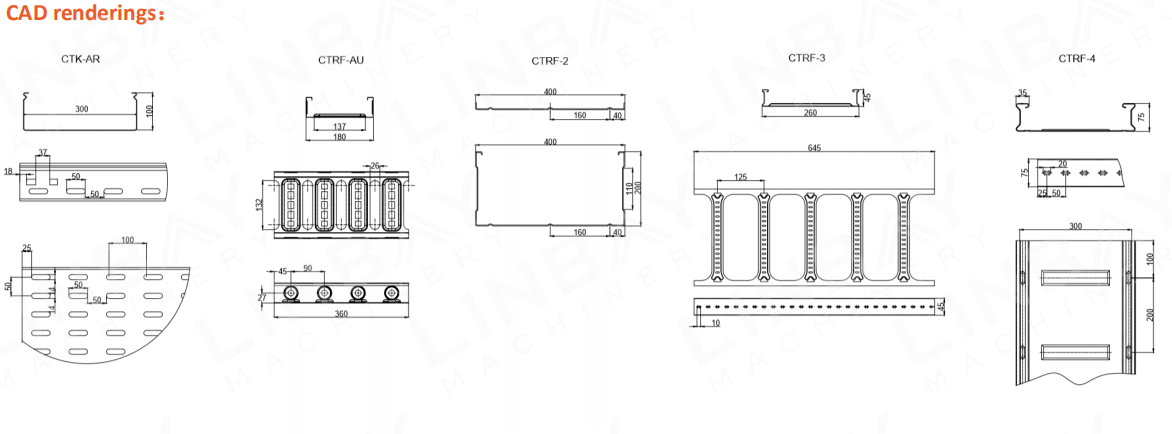

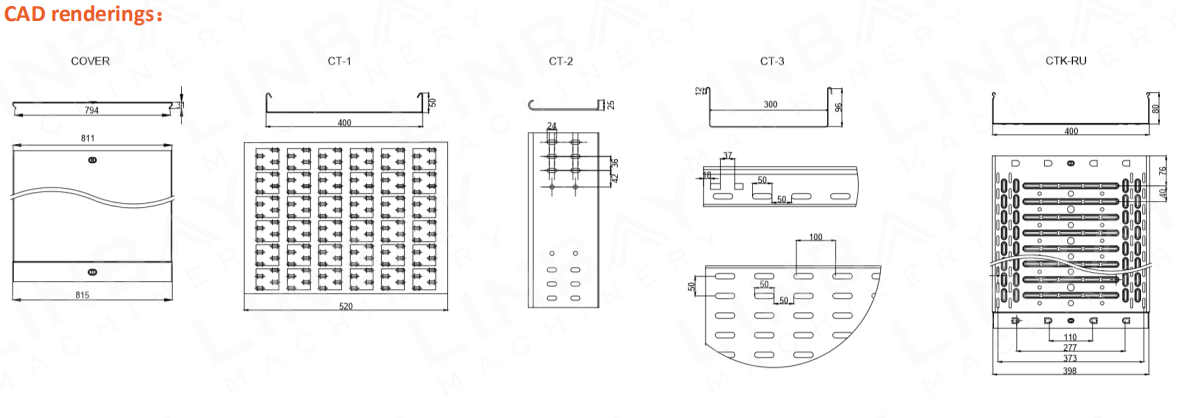

Cable tray roll forming machine is commonly used for cable management in commercial and industrial construction. This intelligent roll former could produce different types of cable trays like: Solid bottom cable tray, Trough cable tray, Channel cable tray, Perforated cable tray, Non perforated cable tray and Trunking cable tray etc. with different raw materials like: hot-dip galvanized steel, pre-galvanized steel, hot-rolled and cold-rolled steel, stainless steel and aluminum. Thickness range of material is 0.6mm-1.2mm or 1-2mm. You could set up 10 different lengths for cable tray. In Electrical Industries, we are able to manufacture more machines like strut channel roll forming machine, DIN rail roll forming machine and Electrical Enclosure Box roll forming machine etc. Linbay make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of Linbay Machinery will ensure you obtain perfectly functional profiles.Application

Real Case A

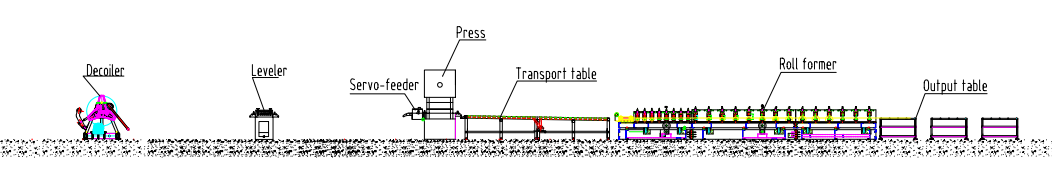

Real Case A  Description: This Cable Tray Line is a new innovation in 2019, using a pre-cut system, cutting blades are embedded into punch mould, so it achieves punch and cut together in punch press. This idea makes working speed faster and save cutting device for our customer. Real Case B

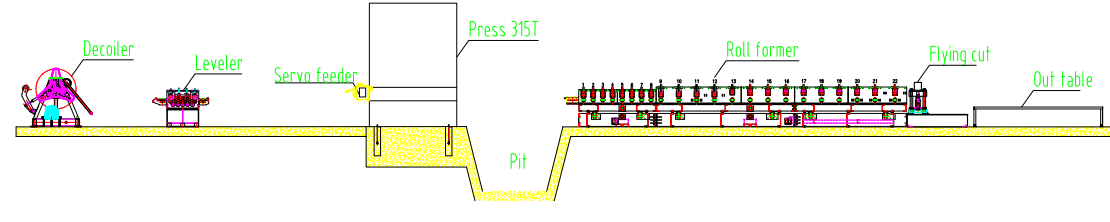

Description: This Cable Tray Line is a new innovation in 2019, using a pre-cut system, cutting blades are embedded into punch mould, so it achieves punch and cut together in punch press. This idea makes working speed faster and save cutting device for our customer. Real Case B  Description: This cable tray production line achieves two types of change in one machine. You could change from cable tray to tray cover (profile to profile) and set up different sizes of cable tray or tray cover from 50 to 600mm(width) from 35 to 100mm(height). This intelligent roll former saves money, space and time for our customer.

Description: This cable tray production line achieves two types of change in one machine. You could change from cable tray to tray cover (profile to profile) and set up different sizes of cable tray or tray cover from 50 to 600mm(width) from 35 to 100mm(height). This intelligent roll former saves money, space and time for our customer. Whole production line of Cable tray roll forming machine

Technical Specifications

| Automatic Cable Tray Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Steel | Thickness(MM): 0.6-1.2, 1-2 |

| B) PPGI | ||

| C) Carbon steel | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | G250 Mpa-G550 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press (Optional) |

| Forming station : | According to your profile drawings | |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Cantilever type | * Forged Iron station (Optional) |

| Forming speed : | 10-20 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | GCr 15 | * SKD-11 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

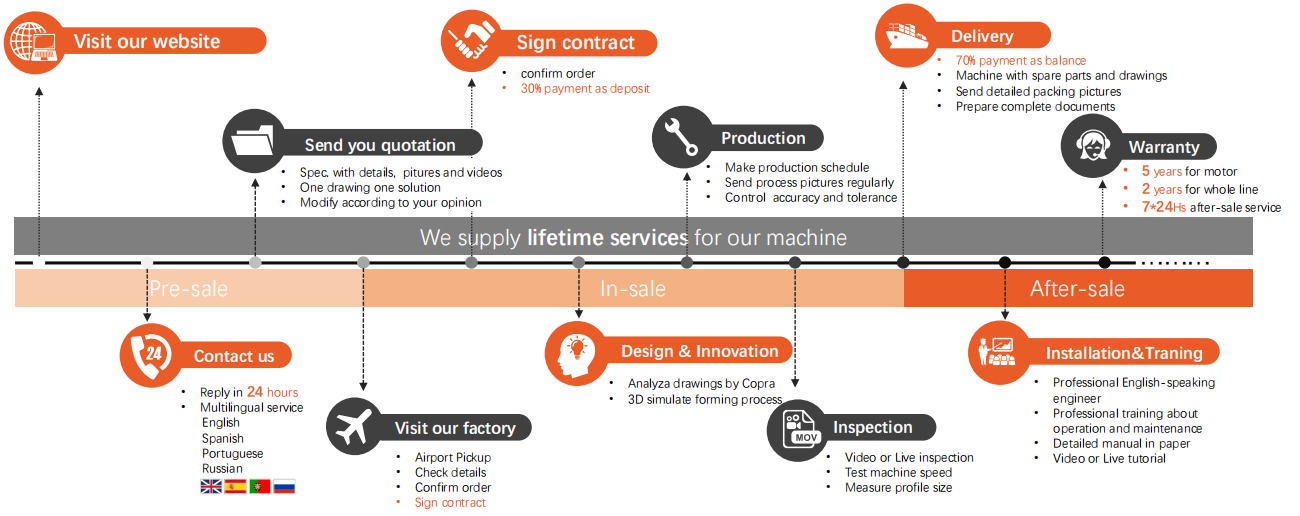

Purchase Service