Description

Linbay Machinery is expert of cable tray roll forming machine and cable ladder roll forming machine manufacturer. We have produced many different kinds of cable tray and cable ladder roll forming machines. Here you will know details of cable ladder roll forming machine.

Normal cable ladder has two parts: the side wall and ladder rung, when you have these two parts made by roll forming machine, you need a welding machine to make them together. The width of cable ladder is the length of rung and the length of ladder is the length of side wall. So cable ladder doesn’t need lot’s of investment, only two roll forming machines, one for cable ladder and one for ladder rung, then a automatic or manual welder. It’s much cheaper than cable tray roll forming machine. And besides, we also made a double row machine, which one line to produce ladder rung and side wall two profiles, but one time only produce one profile, but machine cost is lower than two roll forming machines. But you can see, it needs lots of manual process during production, it has a low production capacity.

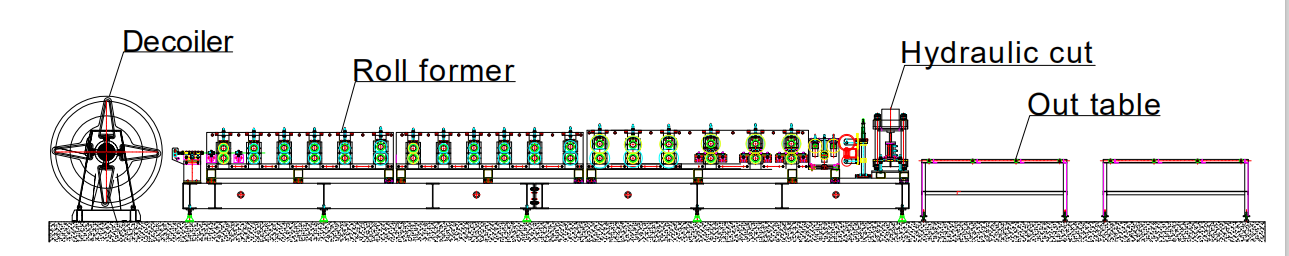

Flow chart:

Decoiler--Roll former--Flyting cut--Out table

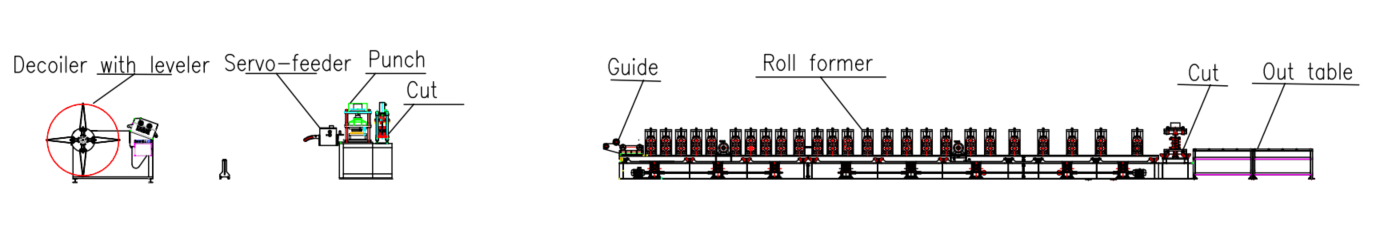

To solve this problem, Linbay Machinery worked with our Chinese customer to design a new type cable ladder roll forming machine. The profile has a good loading capacity, beautiful shape and at same time it allows to produce in a continuous and uninterrupted production line. The thickness of this new type is 1.8mm. It can resist 8-class earthquake and is suitable for earthquake zone countries and nuclear project, the version has been certified by a professional testing institution. Linbay is the first and unique manufacturer of this cable ladder roll forming machine. This new type cable ladder produced by LINBAY only needs to purchase one roll forming machine to realize automatic production. The perforation of this cable ladder is more complicated, the rung is also accompanied by horizontal embossment so each width dimension requires a separate punching mold, so the price of the molds is relatively high. If it is produced by a punching press, we need to use a gantry-type 500-ton punch press. Considering the cost, we use hydraulic punching stations, which are more economical, but the production speed will be much slower. The speed of this line is around 3-4 meters per minute. If we use gantry-type 500-ton punch press, it punches 30 times per minute with a step distance of 300mm, and the production speed can reach 9 meters per minute.

This profile drawing is more complicated, and it needs 25 forming process after punching. Because the sheet is thicker, we use cast iron stands with automatic horizontal movement. This production line uses post-cutting and no-scrap guillotine to save raw materials. Each size has its blade. The advantage of post-cutting is that the shape is more beautiful. At present, this new type cable ladder is relatively rare in the market, and has a price advantage. Actually besides of cable ladder, this production line also can produce cable tray with same profile by changing punch molds, it is a practical production line and is a good investment choice.

Flow chart:

Decoiler with leveler--Servo feeder--Hydraulic punch--Hydraulic pre-cut--Roll former--Hydraulic cut-- Out table

Whole Process of Cable Ladder Roll Forming Machine

Technical Specifications

| Automatic Cable Tray Roll Forming Machine | ||

| Machinable Material : | A) Galvanized Steel | Thickness(MM): 0.6-1.2, 1-2 |

| B) PPGI | ||

| C) Carbon steel | ||

| Yield strength : | 250 - 550 Mpa | |

| Tensil stress : | G250 Mpa-G550 Mpa | |

| Decoiler : | Manual decoiler | * Hydraulic decoiler (Optional) |

| Punching system : | Hydraulic punching station | * Punching press (Optional) |

| Forming station : | According to your profile drawings | |

| Main machine motor brand : | Shanghai Dedong (Sino-Germany Brand) | * Siemens (Optional) |

| Driving system : | Chain drive | * Gearbox drive (Optional) |

| Machine structure: | Cantilever type | * Forged Iron station (Optional) |

| Forming speed : | 10-20 (M/MIN) | * Or according to your profile drawings |

| Rollers’ material : | GCr 15 | * SKD-11 (Optional) |

| Cutting system : | Post-cutting | * Pre-cutting (Optional) |

| Frequency changer brand : | Yaskawa | * Siemens (Optional) |

| PLC brand : | Panasonic | * Siemens (Optional) |

| Power supply : | 380V 50Hz 3ph | * Or according to your requirment |

| Machine color : | Industrial blue | * Or according to your requirment |

How does LINBAY MACHINERY make installation during COVID-19?

The installation of roll forming machine during COVID-19 is for free!

Hereby LINBAY will explain how we do the installation of our roll forming machine.

First, we adjust the machine in our plant, we will ask which size you are going to produce first, we put the machine in the size it is going to produce and adjust all the correct parameters before the shipment, so you do not need to change anything when you got this machine.

Second when we disassemble the machine for debug, we take videos so that you know how to connect them. Each machine has its video. In the video, it will show how to connect the cables and tubes, put the oils, put together the physical structures etc ...

Here is an example of that video: https://youtu.be/p4EdBkqgPVo

Third, when you receive the equipment, you will have a wahtsapp or wechat group, our engineer (He speaks English and Russian) and I (I speak English and Spanish) will be in the group to support you in any doubt.

Fourth, we send you a manual in English or Spanish so that you understand all the meanings of the buttons and how to start the machine.

We have a case that my client from Vietnam received his machine on November 25, and put it on brand at night, and started producing on November 26. And besides this, we have achieved many successes in installing more complicated machines. There is no problem with the installation of your machine. LINBAY offers the best quality and the best service for our clients, especially in this situation. You don't have to wait until the COVID pass. You can produce the profiles right away with our machines.

Q&A

1. Q: What kinds of experience do you have in producing cable ladder roll forming machine?

A: We have exported cable tray production line to Russia, Australia, Argentina, Malaysia, Indonesia. We have produced perforated cable tray, CT cable tray, ladder cable tray and etc. We are confident to solve your cable tray problem.

2. Q: Can I just use one line to produce ladder cable tray and tray cover?

A: Yes, you definitely can use one line to produce cable tray and tray cover. The change operation is simple, you can complete it in half an hour. In this way, this will greatly reduce your cost and time.

3. Q: What is delivery time of ladder cable tray machine?

A: 120 days to 150 days depends on your drawing.

4. Q: What is your machine speed?

A: Machine’s working speed depends on drawing specially punch drawing. Normally forming speed is around 20m/min. Please send us your drawing and let us know your required speed, we would customize it for you.

5. Q: How could you control your machine’s precision and quality?

A: Our secret to producing such precision is that our factory has its own production line, from punching moulds to forming rollers, each mechanical part is completed independently by our factory self. We strictly control the accuracy at each step from design, processing, assembling to quality control, we refuse to cut corners.

6. Q: What is your after-sales service system?

A: We don’t hesitate to give you a two-years warranty period for whole lines, five years for motor: If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.