article expanding on the importance and benefits of using a Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine for industrial and commercial construction projects.

Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine: A Revolution in the Construction Industry

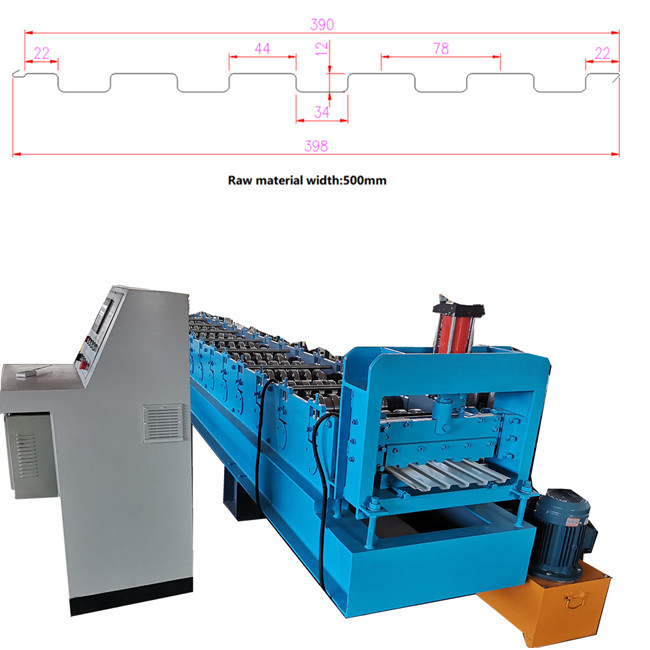

Wuxi Linbay Machinery Co., Ltd. has recently launched a new Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine. The news of the launch of this machine has quickly spread in the construction industry, and industry experts are praising it as a game-changer. The Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine is an advanced equipment that is designed for the fabrication of steel shutter door frames.

The machine is easy to use, cost-effective, and can produce high-quality products at a faster rate compared to traditional manufacturing methods. The machine is designed to roll-form the shape of the steel door frames with a thickness range of 0.5 -1.5mm, which can be adjustable as per requirement.

The machine's performance is exceptional, with a high level of accuracy in the production of the frames. It is suitable for producing various types of frames that are used in commercial and industrial construction projects.

Steel frames are a common feature in many industrial and commercial buildings, as they provide high strength, durability, and resilience. However, the traditional manufacturing process of these frames can be time-consuming and expensive. The Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine eliminates this problem by providing a faster and more cost-effective method of frame production.

Moreover, the machine ensures that the frames produced are of high quality, consistent, and precise in their measurements. This is of utmost importance in construction projects where the frames must fit perfectly to ensure the overall structural integrity of the building.

The Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine has several advantages that make it the perfect choice for construction companies looking to improve their productivity and efficiency. One of the primary benefits is the machine's speed, which can produce up to 25m per minute. This high production rate means that construction companies can produce more frames in a shorter time, leading to faster project completion times and cost savings.

In addition, the machine is versatile and can produce various types of frames of different lengths and sizes, making it ideal for construction projects that require customized frames.

The machine's automation process also ensures that the frames produced are of high quality and consistent. This reduces the likelihood of errors occurring during the production process, leading to less rework and wastage, which further reduces costs.

The Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine is also environmentally friendly compared to traditional manufacturing methods. The machine produces less waste and eliminates the need for chemical treatments that can harm the environment.

The launch of the Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine represents a significant opportunity for the construction industry to improve its efficiency, productivity, and profitability. The machine is a perfect example of the technological advancements being made in the industry, which are reducing costs and production times while increasing quality.

In conclusion, the Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine is an innovative solution for construction companies looking to improve their productivity, efficiency, and profitability. The machine's unique features make it a must-have equipment for any construction project that requires the production of steel frames. The Steel Plate Roller Shutter Door Frame Cold Roll Forming Machine is a game-changer, and it's an exciting time to be in the construction industry.