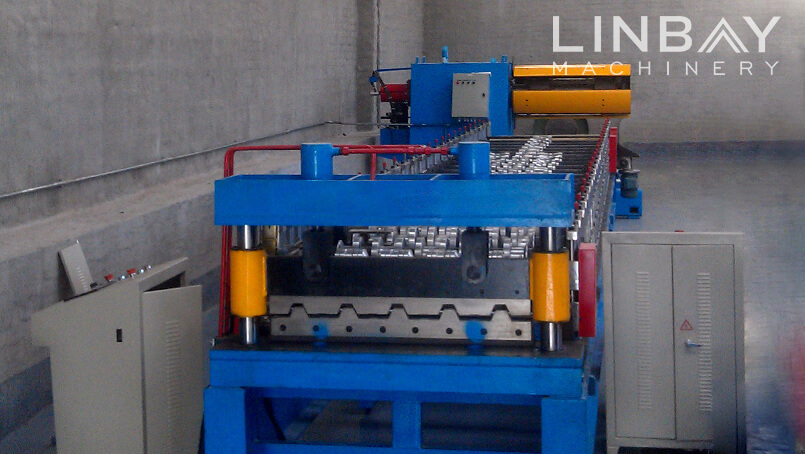

The shelving profiling tools are the result of extensive research and development efforts by Wuxi Linbay Machinery Co., Ltd.'s engineering team. By leveraging advanced technologies and innovative design concepts, the company has been able to create tools that are tailored to the specific needs of the shelving industry. This development represents a significant milestone for the company and underscores its commitment to delivering cutting-edge solutions to its clients.

According to company officials, the new shelving profiling tools are compatible with a wide range of Wuxi Linbay Machinery Co., Ltd.'s roll forming machines, including roofing roll forming machines, glazed tile roll forming machines, C/Z purline roll forming machines, deck floor roll forming machines, guardrail roll forming machines, and cable tray roll forming machines. This versatility ensures that customers can seamlessly integrate the tools into their existing production processes, enabling them to achieve greater efficiency and precision in their operations.

One of the key features of the shelving profiling tools is their ability to accommodate various shelving designs and dimensions. This flexibility is essential for meeting the diverse needs of the shelving industry, where products come in different shapes and sizes. By offering a customizable solution, Wuxi Linbay Machinery Co., Ltd. aims to empower its customers to tackle a broader range of projects and expand their capabilities in the market.

In addition to their adaptability, the new profiling tools also boast advanced automation and control functions. This allows operators to program specific parameters and settings, ensuring consistent and accurate production runs. By streamlining the manufacturing process, Wuxi Linbay Machinery Co., Ltd. enables its customers to reduce downtime, minimize material waste, and ultimately boost their overall productivity.

Furthermore, the shelving profiling tools are engineered to deliver exceptional performance and durability, even under demanding working conditions. Built with high-quality materials and precision craftsmanship, these tools are designed to uphold the robust standards that Wuxi Linbay Machinery Co., Ltd. has become known for. This reliability helps safeguard against unexpected maintenance and repair costs, providing customers with a long-term, cost-effective solution for their shelving production needs.

To support the introduction of the new shelving profiling tools, Wuxi Linbay Machinery Co., Ltd. is rolling out comprehensive training and technical support services for its customers. This initiative reflects the company's dedication to fostering strong, lasting partnerships with its clientele. By arming customers with the knowledge and assistance they need to maximize the potential of the tools, Wuxi Linbay Machinery Co., Ltd. aims to ensure a seamless and successful integration process.

As Wuxi Linbay Machinery Co., Ltd. continues to expand its portfolio of roll forming solutions, the development of the shelving profiling tools marks a pivotal moment in the company's growth trajectory. By addressing the specific needs of the shelving industry and delivering tailored, high-performance tools, Wuxi Linbay Machinery Co., Ltd. is poised to elevate its position as a leading provider of roll forming solutions in the global market.

In conclusion, the introduction of the shelving profiling tools represents a significant advancement for Wuxi Linbay Machinery Co., Ltd., showcasing its unwavering commitment to innovation and customer satisfaction. With these tools, the company is empowering its customers to achieve greater efficiency, precision, and versatility in their shelving production processes. As the company continues to push the boundaries of roll forming technology, it is poised to set new standards for excellence in the industry.